Mold Star™ Series

Easy to Use Silicone Mold Rubber

Mold Star™ silicones cure to soft, strong rubbers which are tear resistant and exhibit very low long term shrinkage. Molds made with Mold Star™ will last a long time in your mold library and are good for casting wax, gypsum, resins, and other materials. Cured Mold Star™ rubber is heat resistant up to 450°F (232°C) and is suitable for casting low-temperature melt metal alloys.

HIGHLIGHTS

One to One Mix Ratio

One to One Mix Ratio

Mold Star™ rubbers are mixed 1A:1B by volume (no weighing scale necessary) for precise measurements even at a very low mass and cure at room temperature with negligible shrinkage.

No Scale Necessary

No Scale Necessary

One to One Mix Ratio

One to One Mix Ratio

No Vacuum Degassing

No Vacuum Degassing

Mold Star™ silicones feature relatively low viscosities making vacuum degassing optional and is not required for most applications. A uniform flow will help minimize entrapped air.

Low Viscosity

Low Viscosity

No Vacuum Degassing

No Vacuum Degassing

Mold Star™ Translucent Series

14T, 19T, 20T, 31T and 40T

Mold Star™ Translucent Series

14T, 19T, 20T, 31T and 40T

Certified Skin Safe, fast curing silicones for making molds or casting into alginate molds. They offer an infinite number of color effects achieved by adding Silc Pig™ silicone pigments or Cast Magic™ effects powders.

Easy to Color

Easy to Color

Fast Cure Time

Fast Cure Time

Certified Skin Safe

Certified Skin Safe

Make Molds Fast

Make Molds Fast

Mold Star™ 16 is available in a 400ml cartridge and is one of the fastest ways to make a silicone mold. With a 6 minute pot life and 30 minute cure time It can even be used in forensics to capture evidence impressions in the field.

Fast Cure Time

Fast Cure Time

Technical and Buying Information

| Select a Product Below | Hardness | Pot Life | Cure Time | Color |

|---|---|---|---|---|

| › Mold Star™ 15 SLOW | 15 A | 50 mins | 4 hrs | Green |

| › Mold Star™ 16 FAST | 16 A | 6 mins | 30 mins | Blue-Green |

| › Mold Star™ 30 | 30 A | 45 mins | 6 hrs | Blue |

| › Mold Star™ 14T | 14 A | 3 mins | 9 mins | Translucent |

| › Mold Star™ 19T | 19 A | 3 mins | 12 mins | Translucent |

| › Mold Star™ 20T | 20 A | 6 mins | 30 mins | Translucent |

| › Mold Star™ 31T | 30 A | 5 mins | 23 mins | Translucent |

| › Mold Star™ 40T | 40 A | 20 mins | 3 hrs | Translucent |

VIDEOS and GALLERIES

Step-by-Step How-To Articles

How to Make Holiday Snowflake Candles Using a Silicone Mold

Learn to make quick and easy reusable silicone molds for candles, perfect for the Christmas season.

How To Choose The Right Method For Making a Rubber Mold

Discover the advantages and considerations behind block molds, brush-on molds, and cavity pour molds.

How To Make a 1 Piece Silicone Cut Mold

Mold Star® 15 is perfect for experienced mold makers or people just starting out.

How To Make a 2 Part Silicone Mold Using Mold Star™ 15

This video outlines the 2-part block mold making technique using silicone rubber.

How To Make Fishing Lures With Mold Star™ & Feather Lite™

Learn How To Make Your Own Fishing Lures With Mold Star™ Silicone and Feather Lite™ Resin

How To Make a Replacement Car Lens Using Crystal Clear 202

How you can replicate a tail light lens of any car using optically-clear resin.

How To Make a Taxidermy Base Using Free Form™ Air Epoxy Putty

How to create a taxidermy habitat base using Mold Star® 16 silicone and Free Form® Air

How to Make a Custom Concrete Fountain

Learn how to make a concrete fountain that looks just like sand using Mold Star® 16 silicone rubber.

How To Create a Silicone Rubber Texture Mat for GFRC Panels

Granary wall inside the barn features woodgrain textures that can be duplicated onto GFRC panels for a shower install.

Tripel X Professional Props Uses TASK™ 16 to Make Props that are Absolutely Indestructible

Tripel X Theming and Props is well known for providing hyper-realistic weapons props for several popular detective shows filmed in New York and Los Angeles.

How To Make a Two Piece Silicone Mold of a Knife

We demonstrate using Mold Star 30 silicone, a platinum silicone for mold making...

How To Make a Mold Star™ 16 Forensics Impression Mold

This mold making tutorial video demonstrates how Mold Star 16 FAST silicone can be used to take forensic impression evidence.

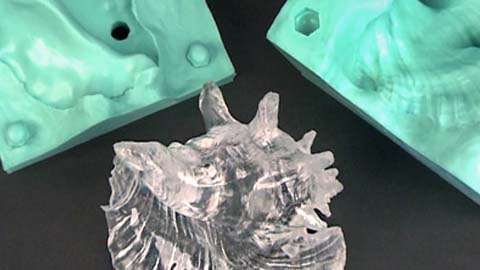

How To Cast a Crystal Clear™ Shell in a Mold Star™ 15 Mold

This sequence demonstrates making a two piece silicone mold using Mold Star® 15 silicone rubber and Crystal Clear® 200

Tutorial - How To Make a Silicone Christmas Tree Candle Mold

In this video, Jeff demonstrates how to make a silicone mold for making candles and scented wax tarts.

How To Make Finger Corals Using Smooth Cast™ Plastic

You can create perfect copies of any piece of original coral using mold rubber and liquid plastic.

How to Make a Silicone Mold of 3D Print

This video demonstrates how to use Mold Star 20T to make a silicone mold of extruded PLA.

How To Make a Gang Mold For Soap Production

This DIY tutorial shows how to make a gang mold of multiple models for production casting of soap.

How To Make a Bear Claw Necklace Replica

How to start with one bear claw and end with 24 perfect copies

How To Make a Mold For Foam Cosplay Armor

Learn how you can make a mold using Mold Star™ 15 silicone to cast FlexFoam-iT!™ 15 SLOW

How To Make a Custom Steering Wheel: Part 1, Silicone Moldmaking

Milo shows how you can make a silicone mold of a steering wheel to create an aftermarket part.

How To Make a Mold For a Concrete Planter

Learn how to make a mold of a glass planter using Mold Star™ 16 Fast.

How To Make a DIY Face Shield Using Mold Star™ 16 Silicone and Smooth-Cast™ 65D Liquid Plastic

Learn how to rapidly make multiple face shields for personal protection

![]()

How To Make a Reusable DIY Silicone Respirator Using Mold Star 20T Silicone Rubber

How you can create a silicone respirator using Mold Star™ 20T skin safe silicone.

How To Make Ear Savers Using Mold Star™ 20T Smooth-Cast™ 65D

Milo shows how to create resin ear savers using a Mold Star™ 20T silicone mold and Smooth-Cast™ 65D casting resin.

How To Make a Cold Cast Prop Wrench Using Real Metal Powders and Smooth-Cast™ 325

Learn How To Make a Metal Cold Cast Prop Wrench With Milo

Complicated Mold Process Made Easy Using Dragon Skin™ and Mold Star™ Silicone

Watch Milo show you how to make a gang mold of some complicated wood carved originals.

How To Make a Foam Prop Sword Using a Silicone 2 Part Mold

How a 3D printed master is used to pour a silicone mold for a prop sword

How To Make a Silicone Mold Using Mold Star™ 15

Learn how to make a simple silicone mold using Mold Star™ 15 liquid silicone rubber.

How To Make GFRC Textured Shower Panels

Multiple GFRC panels of different sizes and shapes will be made from this single texture mat mold.

How To Make a Concrete Sink - From Design To Production

A team of fabrication talent came together to create unique concrete décor elements with an aquatic theme. Custom designed concrete sinks, concrete showers ...

What Have Other People Done With These Products?

![]()

Smooth-On Silicones Pass High Temp Challenge For Wax Casting

Nature's Best experimented and decided to change to Smooth-On platinum silicone rubbers.

RepRap 3D Printer Parts Made with Smooth-Cast® ONYX™

3D printer parts made with Smooth-Cast ONYX and Mold Star 15 molds.