FlexFoam-iT!™ Series

Castable Flexible Urethane Flex Foam

FlexFoam-iT!™ expanding flexible foams are easy to use and durable. They are lightweight, versatile and most are available in easy to measure mix ratios. They can be used for padding/cushion material, gasket material, or to make props and special effects. Vibrant colors can be achieved by adding color pigments.

KEEP OUT OF REACH OF CHILDREN

HIGHLIGHTS

Wide Selection

Wide Selection

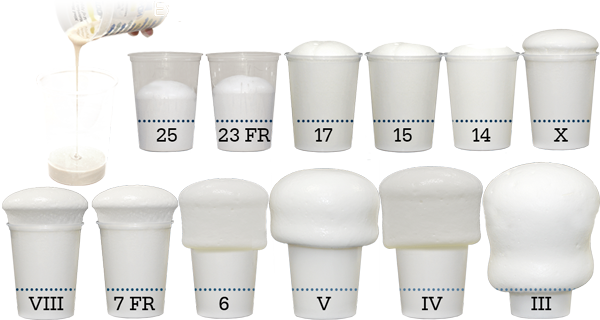

FlexFoam-iT! ® flexible polyurethane foams come in a broad selection of formulations from a 3 pound to a 25 pound density and many others in between. This means you can choose between a high 15 times expansion rate to as low as 2 times expansion to meet your project needs.

Wide Selection

Wide Selection

High Expansion

High Expansion

Low Density

Low Density

FlexFoam-iT!™ IV and 15

TUFF STUFF

FlexFoam-iT!™ IV and 15

TUFF STUFF

FlexFoam‑iT!™ IV and 15 TUFF STUFF have a relatively high tear strength for a low-density foam. They are also stiffer and slightly harder to compress vs. other FlexFoam-iT!™ products.

Gram Scale Required

Gram Scale Required

High Tear Strength

High Tear Strength

Lightweight

Lightweight

FlexFoam-iT!™ 6 and VIII

Pillow Soft

FlexFoam-iT!™ 6 and VIII

Pillow Soft

These foams are very soft and are used for padding/cushion, specialty bed, and orthopedic pillow material applications. Cured foam has very good physical and rebound properties.

No Scale Necessary

No Scale Necessary

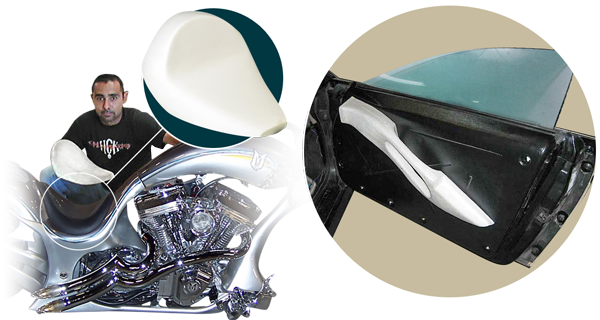

FlexFoam-iT!™ 7 FR

Flame Rated FMVSS-302 Spec

FlexFoam-iT!™ 7 FR

Flame Rated FMVSS-302 Spec

This Federal Motor Vehicle Safety Standard for Flammability of Interior Materials applies to passenger cars, trucks, buses, etc. for making seat cushions, seat backs, arm rests, trim panels, and more.

FlexFoam‑iT!™ 7 FR is widely used to cast custom and "out of production" foam parts.

Flame Rated

Flame Rated

One to One by Volume

One to One by Volume

No Scale Necessary

No Scale Necessary

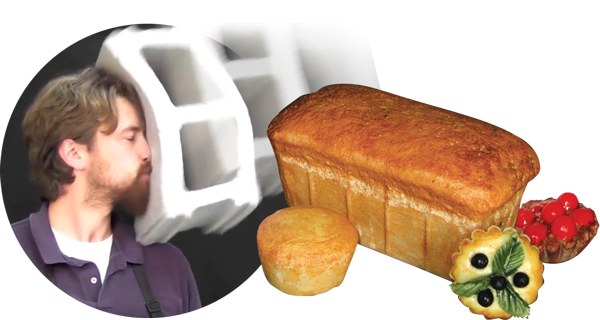

FlexFoam-iT!™ X

FlexFoam-iT!™ X

Easy to use, 10 pound foam perfect for creating props and incredibly realistic food displays.

One to One by Volume

One to One by Volume

No Scale Necessary

No Scale Necessary

FlexFoam-iT!™ 14 and 17

Self Skinning

FlexFoam-iT!™ 14 and 17

Self Skinning

With the right amount of back pressure applied during casting, the surface finish of the cured foam approaches that of a urethane elastomer. The foam is easily colored with SO-Strong™ color tints, UVO™ or Ignite™ fluorescent pigments and is compatible with Cast Magic™ powders for creating a variety of finish effects.

No Scale Necessary

No Scale Necessary

FlexFoam-iT!™ 23

Flame Rated

FlexFoam-iT!™ 23

Flame Rated

This 23 pound foam certifies to UL-94 HB Flame Specification, the Standard for Safety of Flammability of Materials for Parts in Devices and Appliances.

Flame Rated

Flame Rated

Gram Scale Required

Gram Scale Required

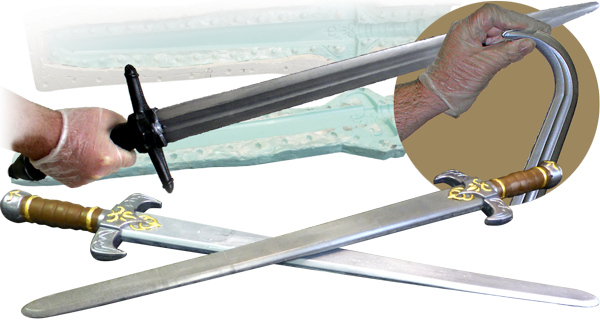

FlexFoam-iT!™ 25

FlexFoam-iT!™ 25

This 25 pound foam is perfect for reproducing smaller details and surface texture versus other foams and is an easy way to reproduce multiple, safe to use, prop weapons for stage and screen.

Gram Scale Required

Gram Scale Required

Technical and Buying Information

| Select a Product Below | Foam Density | Expansion (approximate) |

|---|---|---|

| › FlexFoam-iT!™ III | 3 lb/ft³ | 15 times |

| › FlexFoam-iT!™ IV Tuff Stuff | 4 lb/ft³ | 13 times |

| › FlexFoam-iT!™ V | 5 lb/ft³ | 11 times |

| › FlexFoam-iT!™ 6 Pillow Soft | 6 lb/ft³ | 10 times |

| › FlexFoam-iT!™ 7 FR | 7 lb/ft³ | 8 times |

| › FlexFoam-iT!™ VIII Pillow Soft | 8 lb/ft³ | 7 times |

| › FlexFoam-iT!™ X | 10 lb/ft³ | 6 times |

| › FlexFoam-iT!™ 14 | 14 lb/ft³ | 4 times |

| › FlexFoam-iT!™ 15 Tuff Stuff SLOW | 15 lb/ft³ | 4 times |

| › FlexFoam-iT!™ 17 | 17 lb/ft³ | 3.5 times |

| › FlexFoam-iT!™ 23 FR | 23 lb/ft³ | 2 times |

| › FlexFoam-iT!™ 25 | 25 lb/ft³ | 2 times |

VIDEOS and GALLERIES

Step-by-Step How-To Articles

How To Improve The Surface Finish Of Foam Castings Using Back Pressure

Learn how back pressure results in a tighter cell structure and better foam castings

How To Make a Custom Foam Storage Insert

A Custom Made Foam Insert for Electronics or Other Delicate Equipment

Cosplay Tutorial: How To Cast a Flexible Foam Hellboy Fist

Smooth-On fan Jon N. uses FlexFoam-iT! X to make a durable, lightweight "Hellboy" inspired fist for cosplay.

How to Make Prop Swords out of Flexible Foam

Learn how production companies make prop weapons for use on stage or screen.

How To Make Flexible Foam Prop Cinder Blocks

The scene in Spider Man 3 called for the heroine, Mary Jane, to again be in peril...

How To Make a Flexible Foam Prop Concrete Block

This tutorial shows how Flex Foam-iT! X can be cast to create a realistic cinder block prop.

How To Caste a Prop Engine Block Using FlexFoam® iT! 17

The surface finish of the cured Flex Foam-iT! 17 foam approaches that of a urethane elastomer.

How To Mold and Cast Foam Props - Via Tested.com

Via Tested - How to make simple silicone molds to cast and paint foam replicas of props like shop tools

How To Make a Custom Foam Seat Using Pourable Urethane Foam

Pourable polyurethane foam materials are used to create a unique piece of custom furniture.

How To Make Foam Squishies Using FlexFoam-iT! III Liquid Expanding Foam

How to safely make a foam squishy using Smooth-On FlexFoam-iT! III liquid expanding urethane foam.

How To Repair a Flat Tire Using FlexFoam-iT! 25

See How You Can Use FlexFoam-iT! Foam To Permanently Repair a Tire

How To Repair an Archery Target Using FlexFoam-iT! 15

In this tutorial video, FlexFoam-iT! 15 urethane foam is used to repair an archery target.

How To Make Cosplay Chest Armor Using FlexFoam-iT!™ 15 SLOW Urethane Foam

Learn how you can use FlexFoam-iT!™ 15 SLOW to create lightweight, very strong chest armor.

How To Repair a Tractor Seat Using FlexFoam-iT!™ 15

In this tutorial we show how FlexFoam-iT! 15 can be used to repair a damaged John Deere® tractor seat.

How To Make a Foam Prop Sword Using a Silicone 2 Part Mold

How a 3D printed master is used to pour a silicone mold for a prop sword

What Have Other People Done With These Products?

Tripping The Light Foam-Tastic

Prism artisans have perfected a technique for making incredibly detailed food items

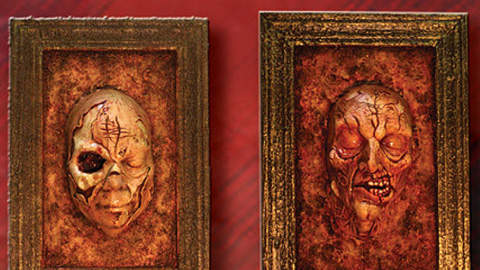

Screamline Studios Makes Props To Die For

Operating out of Mentor Ohio since 1996, Screamline Studios has provided professional design, construction, and coordination for primarily the haunted attraction industry.

Universal Designs Pushes The Envelope Of Costuming

UD Replicas makes amazing costumes using Smooth-On materials.

The Sole of Red Wings Giant Work Boot: Size 638D

The Red Wing Shoe Company was built on America's great promise at the end of the 19th century that if one worked hard enough, one could achieve anything.

A Pillow for the Masses

AC Worx Orthopedic, LLC of Crookston, Minnesota develops a concept for an orthopedic pillow.