Mold Max™ Series

Tin Cure Silicone Mold Rubber

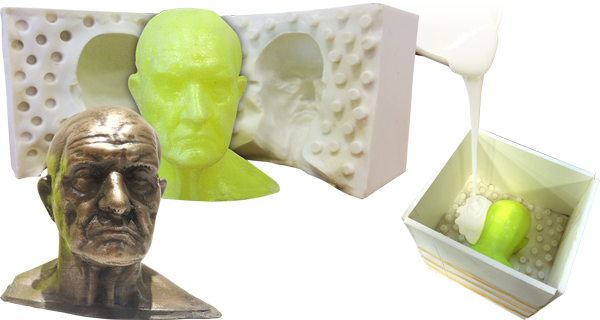

Mold Max™ RTV silicone mold rubbers will reproduce the finest detail from a variety of industrial and art related applications including reproducing prototypes, furniture, sculpture and architectural elements. Use them to cast a variety of materials including wax, gypsum, low melt alloys/metals and urethane, epoxy or polyester resins (without using a release agent).

HIGHLIGHTS

Mold Max™ 10, 20, 25, 30 and 40

There is No Better Silicone Value

Mold Max™ 10, 20, 25, 30 and 40

There is No Better Silicone Value

Used in various production applications from small to large scale like making architectural elements. Mold Max™ 10, 20, 25 and 30 silicone can be thickened with THI-VEX™ additive for brush-on applications.

High Tear Strength

High Tear Strength

Gram Scale Is Required

Gram Scale Is Required

Recommend Vacuum Degassing

Recommend Vacuum Degassing

Mold Max™ XLS™ II

eXtra Low-Shrinkage

Mold Max™ XLS™ II

eXtra Low-Shrinkage

Exhibits very low long-term shrinkage. XLS™ II molds last longer than other silicones in production when casting chemically harsh resins such as epoxies and polyesters as well as urethane foams.

Low Shrinkage

Low Shrinkage

Gram Scale Is Required

Gram Scale Is Required

Recommend Vacuum Degassing

Recommend Vacuum Degassing

Mold Max™ 14NV and 29NV

Low Viscosity

Mold Max™ 14NV and 29NV

Low Viscosity

Offers low viscosity, fast cure and long library life. Mold Max™ 14 NV and 29NV do not require vacuum degassing and will reproduce the finest detail.

Low Viscosity

Low Viscosity

Gram Scale Is Required

Gram Scale Is Required

No Vacuum Degassing

No Vacuum Degassing

Mold Max™ STROKE

Brushable Silicone

Mold Max™ STROKE

Brushable Silicone

Self-thickens for making fast brush-on molds of almost any model. 4 thin layers is all that is necessary to make a strong and durable production mold for casting wax, gypsum, concrete or resins.

Brushable Application

Brushable Application

High Tear Strength

High Tear Strength

Gram Scale Is Required

Gram Scale Is Required

Mold Max™ T Series

Translucent Silicone Rubber

Mold Max™ T Series

Translucent Silicone Rubber

Mold Max™ 10T, 15T and 27T allow for an infinite number of color effects that can be achieved by adding Silc Pig™ silicone pigments or Cast Magic™ powders.

Easy to Color

Easy to Color

Gram Scale Is Required

Gram Scale Is Required

Recommend Vacuum Degassing

Recommend Vacuum Degassing

Mold Max™ 60

Heat Resistant Silicone

Mold Max™ 60

Heat Resistant Silicone

Formulated for applications requiring high heat resistance (up to 560°F/294°C) including making foundry patterns, flat pattern reproductions and casting low-melt metal alloys such as tin and pewter.

High Heat Resistant

High Heat Resistant

Gram Scale Is Required

Gram Scale Is Required

Recommend Vacuum Degassing

Recommend Vacuum Degassing

Technical and Buying Information

| Select a Product Below | Hardness | Pot Life | Cure Time | Color |

|---|---|---|---|---|

| › Mold Max™ 10 | 10 A | 45 mins | 24 hrs | Light Pink |

| › Mold Max™ 20 | 20 A | 45 mins | 24 hrs | Light Pink |

| › Mold Max™ 25 | 25 A | 60 mins | 24 hrs | Purple |

| › Mold Max™ 30 | 30 A | 45 mins | 24 hrs | Pink |

| › Mold Max™ 40 | 40 A | 45 mins | 24 hrs | Mint Green |

| › Mold Max™ 14NV | 14 A | 40 mins | 4 hrs | White |

| › Mold Max™ 29NV | 29 A | 40 mins | 6 hrs | Yellow |

| › Mold Max™ 10T | 10 A | 45 mins | 24 hrs | Translucent |

| › Mold Max™ 15T | 15 A | 45 mins | 24 hrs | Translucent |

| › Mold Max™ 27T | 27 A | 45 mins | 24 hrs | Translucent |

| › Mold Max™ STROKE | 30 A | 30 mins | 16 hrs | White |

| › Mold Max™ 60 | 60 A | 40 mins | 24 hrs | Red |

| › Mold Max™ XLS™ II | 30 A | 40 mins | 24 hrs | Blue |

VIDEOS and GALLERIES

Step-by-Step How-To Articles

DIY Embedded Flower Epoxy End Table

Learn this great technique for making your own unique home décor or to sell as handcrafted masterpieces.

How To Make a Silicone Block Mold of an Irregularly Shaped Model

Learn how to save material and money by making your silicone mold conform to the shape of your model.

How To Recreate an Antique Frame using Mold Max™ 29NV No Vacuum Required Silicone

Learn how to use Mold Max 29NV for creating a high-detail silicone mold

How To Make a 2-Part Mold of an Architectural Bracket

After Hurricane Katrina hit New Orleans, city native Chep Morrison replicated an ornate bracket

How To Make a Breakaway Glass Window Pane

This tutorial takes you step-by-step through the process of making a large window pane suitable for using as a breakaway glass prop for stage or movie special effects.

How To Make a Star Trek Klingon Disruptor with Mold Max™ Silicone and Smooth-Cast™

This tutorial outlines making a mold of a replica Klingon Disruptor pistol from the Star Trek television series.

How To Make a 2 Piece Silicone Mold to Cast a Police Baton Prop

This step-by-step tutorial shows the process of making a two-piece block mold from a police baton using Mold Max® 30 silicone rubber. It also shows how to cast a reproduction using TASK 13 semi-rigid resin.

How To Mold & Cast An Alligator Snapping Turtle

Wildlife Art Creations chronicled their processes used to make exact duplicates of this dinosaur.

How To Make Antler Reproductions Using Reverse Molding

In this how-to, Tony Breedlove uses a cavity pour technique that yields perfect antler castings every time.

Making A One Piece Cut Block Mold

A one piece cut block mold is a popular mold making method that has some definite advantages.

How To Make a Block Mold of a Four Legged Animal

This howto shows where to properly place air vents and also where to make your extraction cut line.

How To Vent a Silicone Mold to Eliminate Bubbles In Casting

This sequence chronicles Mr. Ross's process in successfully reproducing this model using an advanced mold making technique.

How To Mold and Rotocast a Wooden Sculpture

Learn how Dennis Collier Studios molds and casts stunning carved wood pieces

![]()

How To Measure Silicone By Weight - Mold Max® 20

How to use a gram scale to accurately weigh rubbers, plastics and other materials.

How to Double Mix and Pour Mold Max® 14NV Silicone

Inadequate mixing is the number one reason for silicone rubber not curing. This video demonstrates the double mix and pour technique.

How To Vacuum Degas Silicone - Mold Max™ 30

How to vacuum silicone to eliminate entrapped air and remove bubbles from your finished mold or casting.

How To Cast Pewter Into Mold Max® 60

Mold Max® 60 was developed for high-heat resistance applications.

How To Make a 2 Part Mold of an Antique Rifle

How to make a two piece silicone block mold of an antique Kentucky long rifle

How To Make a 2 Part Silicone Mold Using Mold Max™ 25

In this step-by-step photo gallery, a 2-part rubber mold is made to duplicate an industrial wheel.

How To Mold and Cast Foam Props - Via Tested.com

Via Tested - How to make simple silicone molds to cast and paint foam replicas of props like shop tools

How To Create a Matrix Mold or Cavity Pour Mold Using Mold Max™ 30

Creating A Cavity Pour Mold Using Mold Max® 30

What Have Other People Done With These Products?

Molding an Original Ghostbusters® Prop

Artist Paul Francis shows how he reproduces an original Terror Dog from Ghostbusters®

Sculptor James Day Expresses His Visionary Realism

James uses PMC®-744, OOMOO® 30 and Mold Max® 30 rubber

Betting It All On The Rocks

Employing the right materials to meet an impossible deadline.

Reconstructing a Stone-Age Embrace

Paleoartist Tyler Keillor brought a "paleo-trifecta" of art, science and innovation to bear in order to help reconstruct this ancient scene.

Freeze Cast Process uses Smooth-On Rubber for Precision Casting

Rubber molds can be made quickly and will accommodate the expansion of water during the freezing process.

Making Spirits Bright

Creating a world class display that would be viewed by millions of visitors to New York City’s Christmas Wonderland.

Restoring a 300 Year Old Plaster Frame

In this example, a plaster frame is reproduced using Mold Max® 10 silicone.

Themed Rock Display at New York Auto Show

Two scenic companies collaborated on a project to launch the new Jeep Liberty

Animatronic Zombie Made Using Mold Max™ 10T Silicone

MisteRoboto has created an extremely realistic zombie animatronic using Mold Max® 10T

Rejuvenating the Landmark Russian Tea Room

Felber Ornamental Plastering produced highly detailed interior & exterior decorative elements.

Gary Willett's Animatronic Monster Comes To Life!

Gary has turned a part time hobby into a full-fledged lifelike animatronic.

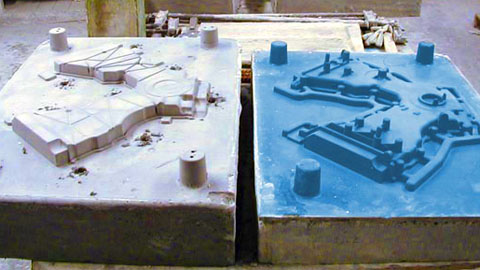

Sand Casting Patterns made with Mold Max™ XLS

In the process of sand casting, a pattern is a replica of the original object to be cast.

On the Set of 'The Santa Clause 2'

After the success of the original 'The Santa Clause', it was only natural that the second installment be bigger and better than the original.

Red Buses of Glacier National Park Restored with Crystal Clear®

A recent Crystal Clear™ industrial application involved Ford Motor Company's restoration of "The Red Buses Of Glacier National Park" in Montana.

Miniature Realism Created By Robert

Robert's custom cast resin action figure accessories are well know for their ultimate detail.

Labor of Love for the Tall Masts

Ken Gardiner started making models 39 years ago as a hobby based on what he learned from his father. About eight years later, Ken decided it might be worthwhile making a living out of it.

Ultra Miniature Aircraft Accessories By Modern Hobbies LLC

Modern Hobbies LLC® is THE place for "Small Scale" jet modelers looking for rare, hard to find items to outfit their modern military aircraft.

Puppets Come To Life At Waken Productions

Waken Productions, Inc. was spawned from a successful machine design company.

A Pillow for the Masses

AC Worx Orthopedic, LLC of Crookston, Minnesota develops a concept for an orthopedic pillow.

Making a Difference During the COVID-19 Pandemic With ATTA Inc.

ATTA Inc. in NYC donates over 1,200 visors made with Smooth-On materials

Reaching for New Heights with Smooth-Cast™ 320 Liquid Plastic

Smooth-On has been a supplier to manufacturers of sports and recreational equipment for years. An example of such products involves Indoor Rock Climbing Gyms.