Dragon Skin™ Series

High Performance Silicone Rubber

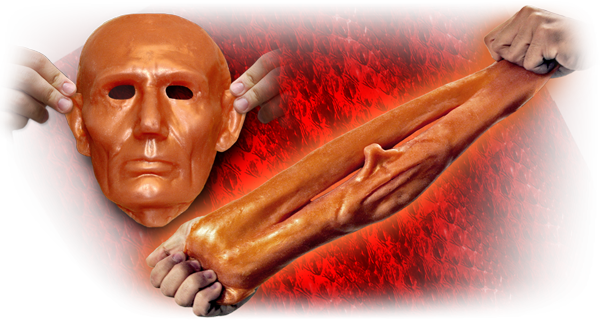

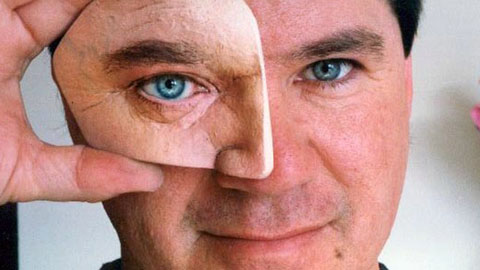

Dragon Skin™ silicones are used for a variety of applications, ranging from creating skin effects and other movie special effects to making production molds for casting a variety of materials. Due to their superior physical properties and flexibility, they are also used for medical prosthetics and cushioning applications.

HIGHLIGHTS

Strong and Stretchable

Strong and Stretchable

The superior physical properties and flexibility of Dragon Skin™ rubbers means that cured Dragon Skin™ is very strong and very "stretchy". It will stretch many times its original size without tearing and will rebound to its original form without distortion.

High Tear Strength

High Tear Strength

Easy to Color

Easy to Color

Certified Skin Safe

Time Tested, Versatile Special Effects Material

Certified Skin Safe

Time Tested, Versatile Special Effects Material

Dragon Skin™ are used around the world to make spectacular skin and creature effects that are skin safe and certified by an independent laboratory to the OECD TG 439 certification. No animals were used in testing.

Certified Skin Safe

Certified Skin Safe

One to One Mix Ratio

One to One Mix Ratio

Easy To Use – Dragon Skin™ high performance platinum cure silicone rubbers can be mixed 1A:1B by volume without need for gram scales or by weight for precise measurements even at a very low mass and cure at room temperature with negligible shrinkage.

No Scale Necessary

No Scale Necessary

Recommend Vacuum Degassing

Recommend Vacuum Degassing

Dragon Skin™ NV Series

NV means No Vacuum Needed

Dragon Skin™ NV Series

NV means No Vacuum Needed

These low viscosity formulations of Dragon Skin™ do not require vacuum degassing and have excellent elongation, stretch, allowing you to eliminate the need for a cut seam on some models. They exhibit exceptional performance properties such as high tensile strength.

No Vacuum Degassing

No Vacuum Degassing

Low Viscosity

Low Viscosity

No Scale Necessary

No Scale Necessary

Technical and Buying Information

| Select a Product Below | Hardness | Pot Life | Cure Time |

|---|---|---|---|

| › Dragon Skin™ 10 VERY FAST | 10 A | 4 mins | 30 mins |

| › Dragon Skin™ 10 FAST | 10 A | 8 mins | 75 mins |

| › Dragon Skin™ 10 MEDIUM | 10 A | 20 mins | 5 hrs |

| › Dragon Skin™ 10 SLOW | 10 A | 45 mins | 7 hrs |

| › Dragon Skin™ 10 NV | 10 A | 15 mins | 75 mins |

| › Dragon Skin™ 10 AF Anti Fungal | 10 A | 20 mins | 5 hrs |

| › Dragon Skin™ 15 | 15 A | 40 mins | 7 hrs |

| › Dragon Skin™ 20 | 20 A | 25 mins | 4 hrs |

| › Dragon Skin™ 20 NV | 20 A | 6 mins | 30 mins |

| › Dragon Skin™ 25 NV | 25 A | 10 mins | 30 mins |

| › Dragon Skin™ 30 | 30 A | 45 mins | 16 hrs |

| › Dragon Skin™ FX‑ Pro™ | 2 A | 12 mins | 40 mins |

VIDEOS and GALLERIES

Step-by-Step How-To Articles

Molding and Casting a Cosplay Cloak Brooch

Learn to make a mold and casting of a translucent cloak brooch perfect for cosplay.

How To Choose The Right Method For Making a Rubber Mold

Discover the advantages and considerations behind block molds, brush-on molds, and cavity pour molds.

How To Make a Needle Insertion Trainer

There are many benefits to making your own needle insertion training pads vs. using pre-made pads.

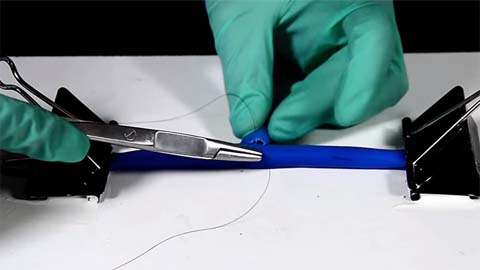

How To Make Your Own Suturable Vessels

This tutorial will show you how to create suturable vessels using Dragon Skin silicone

Cosplay Tutorial: How to Make a Silicone Brush Mold for a Hellboy Fist

Smooth-On fan Jon N. shows how he makes a mold for a large "Hellboy" inspired fist for cosplay.

How To Make a Prototype Impact-Resistant Rectangular Sifting Mat

Watch how a CNC routed prototype turns into a durable urethane finished product

How to Make a Silicone Gel-Filled Zombie Prosthetic

How to create a silicone gel filled appliance, paint the piece, and adhere it to the actor.

How To Make a Quick Silicone Wound Prosthetic

Making and applying professional quality wound prosthetics.

How To Make a Simple Silicone Halloween Sock Mask

Make a quick and easy brush on silicone Halloween mask that looks like it took days to create...

How To Make a Brush-On Mold Using Dragon Skin™ Silicone Rubber

The extreme flexibility of Dragon Skin makes it ideal for creating one piece glove molds.

Moldmaking and Casting For a Woodgrain Finish

In this how-to, Smooth-Cast® 320 resin is cast in a Dragon Skin® silicone mold to reproduce woodgrain

How To Make a Silicone Glove Mold and Faux Wood Casting

Dragon Skin® is excellent for brush on molds. A Dragon Skin® mold can be turned completely inside out without risk of tearing.

How To Make a Silicone Severed Head Prop

Shell Shock® and Plasti-Paste® can be used to make a strong, inexpensive mold which can be used for casting silicones.

How To Make a Prop Rattlesnake Using Dragon Skin™ Silicone

On a recent job, Blair Benjamin needed to reproduce a rattlesnake for an independent film project.

High Tech Materials Create a Horrific Zombie

Zombies are more popular than ever in TV shows, movies, Zombie-walks, Zombie Parties and more.

How To Reproduce a Sea Sponge using Liquid Plastic

You can create perfect copies of any original sea sponge model using mold rubber and liquid plastic.

How To Create a Zombie Makeup Using Silicone Rubber

Smooth-On fan Leo V. shows how to make and apply a zombie makeup using the Ultimate Zombie Kit.

How To Make a Silicone Pregnancy Overlay - Part 2

Silicone rubber and foam are applied to the mold surface to create a realistic pregnancy overlay.

How To Use Dragon Skin™ Silicone to Reproduce Antlers

James Edgar knows that accurately reproducing antlers is one of the most common tasks in the business.

How To Make a Seamless Resin Casting Using Dragon Skin™ 10 NV

This tutorial shows how a seamless mold can be made using Dragon Skin™ 10 NV silicone rubber.

How To Make a Silicone Glove Mold for a Resin Cosplay Helmet

Jon N. shows us how he made a glove mold for his cosplay helmet

![]()

How To Create a Realistic Silicone Wound using Smooth-Cast™ 300 and Dragon Skin™ FX Pro

Learn how to make a plate mold for a wound, and how to cast and apply a Dragon Skin™ FX-Pro™ prosthetic.

Seamless Silicone Glove Mold - Making Things with Milo

The challenge: Make a seamless mold of a sculpted hand with same-day turnaround for castings.

Making a Mold of a Complex Anatomical Model

Join Milo as he makes a mold of a complicated skull model.

![]()

How To Make a Fake Bloody Hand Prop Using Alja-Safe™ and Dragon Skin™ 10NV

We show how to make a realistic rubber hand with fake bloody accents.

Complicated Mold Process Made Easy Using Dragon Skin™ and Mold Star™ Silicone

Watch Milo show you how to make a gang mold of some complicated wood carved originals.

Live! - Casting Silicone With Milo

Milo demonstrates how to cast silicone and explain how to choose the proper mold material for your application.

How to Make a Cavity Pour Mold Using Dragon Skin™ 20 NV

How to Make a Cavity Pour Mold Using Dragon Skin™ 20 NV

What Have Other People Done With These Products?

Hyper Realistic Silicone Art From Tom Kuebler

Tom creates his works of surreal art using silicone, foam, resin, any material which triggers his imagination.

Bringing a Wild Vision Of The Joker To Life!

Frank Ippolito created his own vision of The Joker by creating a multi-piece silicone appliance makeup

Building a Giant Animatronic Octopus for T-Rex Cafe Themed Restaurant

In this time-lapse video, Daddona Studios fabricates pieces for a 'T-Rex Cafe'

One-of-a-Kind Santa Sculptures

Linda Kays-Biviano used Dragon Skin® for creating the skin, giving the Santas a very life-like appearance.

Lifelike Babies Created with Dragon Skin™ Silicone

Tasha Edenholm creates hand made and "One-Of-A-Kind" lifelike babies with Dragon Skin™ Silicone

The Scarehouse - Pittsburgh's Ultimate Haunted Attraction

To maintain their reputation as one of the most advanced haunts in the U.S.,The Scarehouse incorporates Smooth-On silicones

![]()

Smooth-On Silicones Pass High Temp Challenge For Wax Casting

Nature's Best experimented and decided to change to Smooth-On platinum silicone rubbers.

A Whale Of a Tale About Smooth-On Rubber

Smooth-On silicone takes the lead in making animatronic whales.

The Many Faces Of Guy Louis XVI

It is simply impossible to readily discern that Guy's figures are not alive.

Soft, Stretchy Dragon Skin™ Rubber Keeps Production Moving

Reproduce an extremely rare hand carved wood collection from the 17th century.

Toronto Fans Go Wild for Hockey Character Costumes by David Pea

When the Toronto Maple Leafs NHL hockey team needed eye-catching costumes for their 3 new mascots, they needed only to look in the backyard.

Universal Designs Pushes The Envelope Of Costuming

UD Replicas makes amazing costumes using Smooth-On materials.

Captain America Tribute Helmet Made from Smooth-Cast™ 45D

When Jonathan Hunt was searching out materials to create 'Captain America' style helmets for his clients, he was looking for very particular properties.

Arcana Workshop Brings to Life Xenomorph with Smooth-On Products

There is a new creature roaming the halls of Smooth-On. It stands seven feet tall and has razor sharp teeth!

Disaster Simulation and Training Exercise, Avalanche

Smooth-On worked with St. Luke's Hospital for this Avalanche Disaster Simulation Event