URE-FIL™

Powder Fillers

URE‑FIL™ fillers disperse easily in Smooth-On materials. They can be added in different proportions to achieve a variety of working properties and effects. Some fillers are designed for cost-savings, others are designed for specific casting effects or improved physical properties. Other URE‑FIL™ fillers are designed specifically for thickening materials for brush-on or trowelable application.

HIGHLIGHTS

URE-FIL™ 3

Use Less Resin, Lower Cost

URE-FIL™ 3

Use Less Resin, Lower Cost

Ceramic filler which is added to urethane resins and castable epoxies to reduce cost. Recommended starting mix ratio is 1A to 1B to 1 part URE‑FIL™ 3.

URE-FIL™ 5

URE-FIL™ 5

The best choice for creating a wood grain effect. Note: your mold must reflect the wood grain pattern of the original model. Mix 1 part filler with 1A:1B of Smooth‑Cast™ 320 resin and cast into mold. After demold, apply wood stain or shoe polish to casting surface to bring out wood grain effect.

URE-FIL™ 7

URE-FIL™ 7

Improves dimensional stability in urethane resins and castable epoxies. Often added to materials to make them flame-resistant. URE‑FIL™ 7 can be mixed with Smooth‑Cast™ 325 and SO‑Strong™ color tints to create marble effects. Recommended maximum mix ratio is 1A:1B to 2 parts filler. A mix ratio of 1A:1B to 3 parts filler will make the plastic trowelable, but the cured plastic will also be brittle.

URE-FIL™ 9

URE-FIL™ 9

Fumed‑silica based thickening agent primarily used with liquid urethane and silicone rubbers for brush‑on moldmaking applications. URE‑FIL™ 9 is added in small amounts to the mixed rubber until the desired viscosity is achieved. URE‑FIL™ 9 can also be added to liquid urethane resins to create casting effects and to thicken the material for trowelable casting applications.

URE-FIL™ 11

URE-FIL™ 11

Fiber‑based filler that can be added to Smooth‑On urethane and silicone rubbers, urethane plastics and epoxies to thicken for brush‑on applications. URE‑FIL™ 11 can be used with all Smooth‑On silicones, including those which do not respond to THI‑VEX™ such as Ecoflex™ 00‑30 and Mold Max™ 40.

URE-FIL™ 15

URE-FIL™ 15

Micro‑balloons that can be added to Smooth‑On urethane plastics and epoxies to create very light weight castings. Castings which float on water can be created by using proper proportions of URE‑FIL™ 15. A casting resin filled with a large proportion of URE‑FIL™ 15 can be described as a ‘syntactic foam’, non‑expanding foams which are stiffer, stronger and more water resistant than water‑blown expanding urethane foams of the same density.

URE-FIL™ 17 and 19

URE-FIL™ 17 and 19

Pure aluminum pellet fillers used with liquid epoxy and urethane resins to improve thermal conductivity, dimensional stability, reduce shrinkage in large mass castings, etc. Can also be used to add evenly distributed weight to metal cold-castings and to create artistic casting effects.

Technical and Buying Information

| Select a Product Below | Description |

|---|---|

| › URE-FIL™ 3 | Ceramic Filler to Reduce Cost of Casting |

| › URE-FIL™ 5 | Filler for Creating a Wood-Grain Effect |

| › URE-FIL™ 7 | Urethane Filler for Dimensional Stability |

| › URE-FIL™ 9 | Fumed-Silica Based Thickening Agent |

| › URE-FIL™ 11 | Fiber Filler for Urethane and Silicone |

| › URE-FIL™ 13 | Poly-Blend Filler for Urethane |

| › URE-FIL™ 15 | Micro-Balloons to Reduce Casting Weight |

| › URE-FIL™ 17 | Aluminum Pellet Filler (400 micron) |

| › URE-FIL™ 19 | Aluminum Pellet Filler (1200 micron) |

VIDEOS and GALLERIES

Step-by-Step How-To Articles

How To Rotocast a Hollow Part Using Smooth-Cast™ 65D

Creating a hollow casting with high impact resistance by rotating a mold while casting.

How To Create a Marble Effect Using Urethane Plastic

Creating a realistic cast marble effect is possible with Smooth-Cast® 325 liquid plastic.

Moldmaking and Casting For a Woodgrain Finish

In this how-to, Smooth-Cast® 320 resin is cast in a Dragon Skin® silicone mold to reproduce woodgrain

How To Handle Large Undercuts In The Brush-On Mold Making Process

Planning is the key to success in any mold making project...

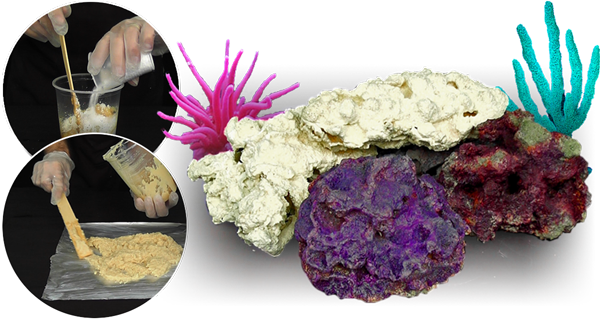

How To Create Your Own Cast Live Rock Using Smooth Cast™ 321

Making your own live rock offers an infinite variety of design / color possibilities.

Creating Realistic Wood Replications Using Smooth-Cast™ 320 Resin and URE-FIL™ 5

Milo shows how to cast resin duplicates of wooden models

What Have Other People Done With These Products?

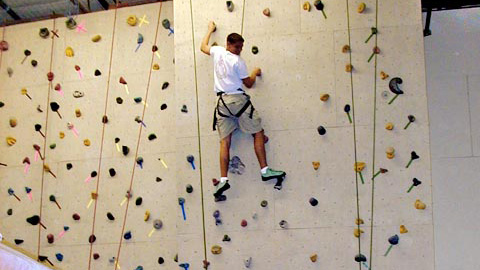

Reaching for New Heights with Smooth-Cast™ 320 Liquid Plastic

Smooth-On has been a supplier to manufacturers of sports and recreational equipment for years. An example of such products involves Indoor Rock Climbing Gyms.