Model Making

Model makers the world over know that Smooth-On silicone rubbers and liquid plastics as the perfect combination to reproduce their creations and drive production.

Smooth-On's Mold Max™ Silicones have become the industry standard for making molds that capture very fine detail down to a "finger-print". With several to choose from, the Mold Max™ line covers most mold making scenarios and offers the model maker tremendous versatility.

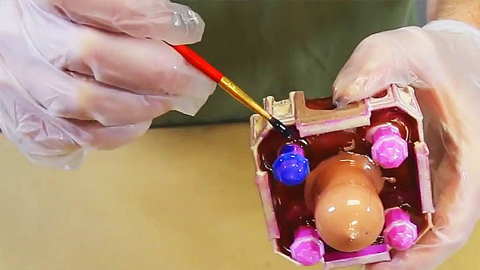

Smooth-Cast™ plastics and TASK™ plastics are then used to cast into these molds to make exact reproductions. SO-Strong™ color tints and a variety of fillers can be added to create an infinite number of effects. Cured plastics are also easily painted , giving the user complete creative control over the modeling outcome.

Featured Step-by-Step How-To's

How To Make Fishing Lures With Mold Star™ & Feather Lite™

Learn How To Make Your Own Fishing Lures With Mold Star™ Silicone and Feather Lite™ Resin

How To Make a Replacement Car Lens Using Crystal Clear 202

How you can replicate a tail light lens of any car using optically-clear resin.

How To Mold and Cast a Record That Actually Plays

How moldmaking and casting expand horizons for a seminar graduate whose passion is 78 RPM records

How To Restore an Antique Picture Frame Using Equinox™

In this example, Equinox™ silicone putty is used to mold a section of an antique wooden picture frame.

How To Cast a Custom Scenery For a Model Railroad

Mold making and casting gives model railroaders options for creating custom scenic display pieces.

The Easiest Brushable Urethane To Mix!

EZ~Mix® 40 is a liquid / liquid system, making it perfect for novice mold makers.

How To Make a Block Mold of a Four Legged Animal

This howto shows where to properly place air vents and also where to make your extraction cut line.

How To Add Color Effects To a 3D Printed Part Using XTC-3D™

This video demonstrates how to use XTC-3D epoxy coating to smooth and apply color to a 3D printed architectural model.

How To Cast Pewter Into Mold Max® 60

Mold Max® 60 was developed for high-heat resistance applications.

View All How-To Videos and Galleries ›

What People Have Done With These Materials

Molding an Original Ghostbusters® Prop

Artist Paul Francis shows how he reproduces an original Terror Dog from Ghostbusters®

Daft Punk Helmet by Volpin Props

This helmet was the fruit of 17 months of work.

RepRap 3D Printer Parts Made with Smooth-Cast® ONYX™

3D printer parts made with Smooth-Cast ONYX and Mold Star 15 molds.

Resin Figure Gallery

This gallery of images is a collection of work by various artists casting resins to produce figures.

Moen Uses Smooth-On To Spark Development

Moen uses the full spectrum of Smooth-On tin and platinum-based silicone rubbers to develop and refine proposed design

Model Maker Crafts Award Winning Designs

Shawn Casidy depends on Smooth-On Mold Max® and OOMOO® silicone rubber molds to reproduce amazing detail

Fossil Hunters Use SORTA-Clear™ Silicone

Nelson Maniscalco and Marty Shemella are highly skilled in reproducing detailed fossils and skeletons.

Casting Intaglio Gems

How the Carlos Museum's lab uses silicone rubber molds to make accurate and reproducible casts from ancient gems.

Custom Fishing Lures created with Feather Lite™

Shawn Rutledge has found success and scored some big fish with his lures.

Tripping The Light Foam-Tastic

Prism artisans have perfected a technique for making incredibly detailed food items

Imaginarium Ventriloquist Dummies Come To Life

Albert skillfully sculpts each character in clay then molds them with Mold Max® 30 silicone mold rubber and Featherlite®

Puppet legacy lives on with Smooth-On Products

In 1938 a 15 year old boy created and staged his marionette version of Puss in Boots for children at the Nashville Public Library.

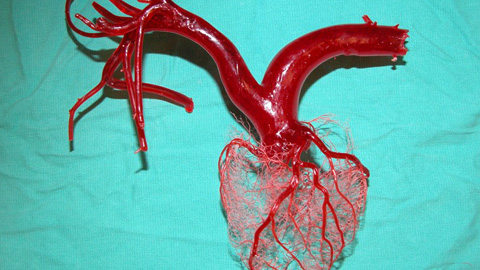

Heart to Heart With Smooth-On® Silicones

Jesse Rios is a researcher working with the Texas Heart Institute at St. Luke's Hospital in Houston.

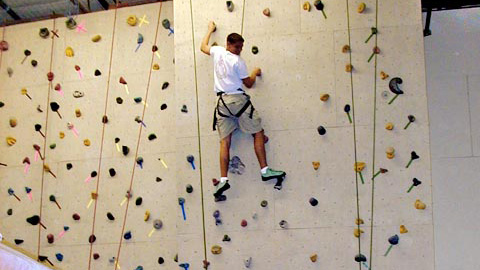

Reaching for New Heights with Smooth-Cast™ 320 Liquid Plastic

Smooth-On has been a supplier to manufacturers of sports and recreational equipment for years. An example of such products involves Indoor Rock Climbing Gyms.

Miniature Realism Created By Robert

Robert's custom cast resin action figure accessories are well know for their ultimate detail.

Labor of Love for the Tall Masts

Ken Gardiner started making models 39 years ago as a hobby based on what he learned from his father. About eight years later, Ken decided it might be worthwhile making a living out of it.

Ultra Miniature Aircraft Accessories By Modern Hobbies LLC

Modern Hobbies LLC® is THE place for "Small Scale" jet modelers looking for rare, hard to find items to outfit their modern military aircraft.

Puppets Come To Life At Waken Productions

Waken Productions, Inc. was spawned from a successful machine design company.

Captain America Tribute Helmet Made from Smooth-Cast™ 45D

When Jonathan Hunt was searching out materials to create 'Captain America' style helmets for his clients, he was looking for very particular properties.

![]()

Award-Winning Artist Brings Dolls to Life

Artist bridges the gap between fantasy and reality with automated life-like dolls.