EpoxAcoat™

Surface Coat Epoxies

Thixotropic epoxy gel coats widely used for hand laminating/ tooling applications. Tough, strong surface coat resins which cure at room temperature offering exceptional abrasion resistance. EpoxAcoat™ RED, EpoxAcoat™ GREY and EpoxAcoat™ WHITE are easy to use, wet out well over a variety of surfaces and will coat vertical surfaces without sagging. EpoxAcoat™ HT offers high heat resistance.

HIGHLIGHTS

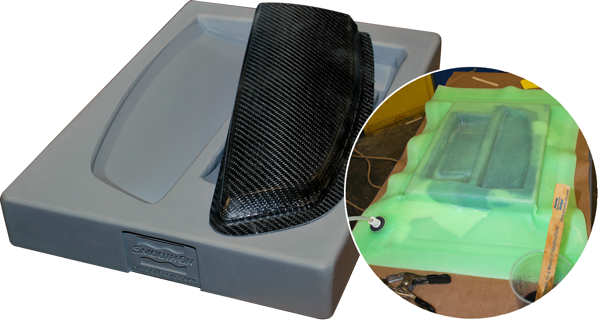

Composites Tooling

Composites Tooling

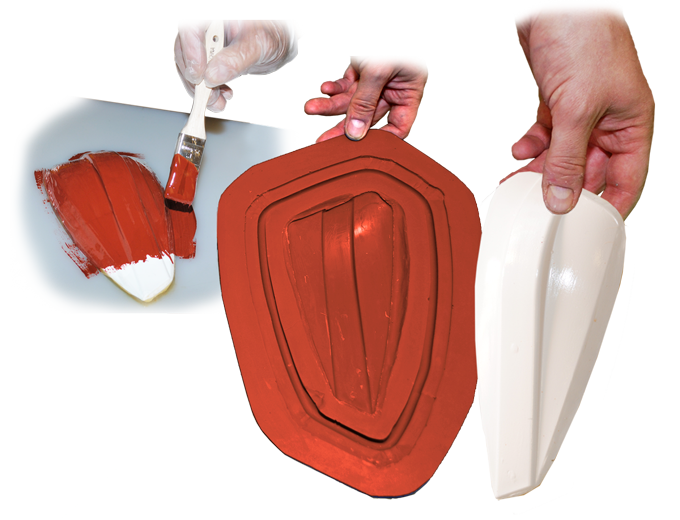

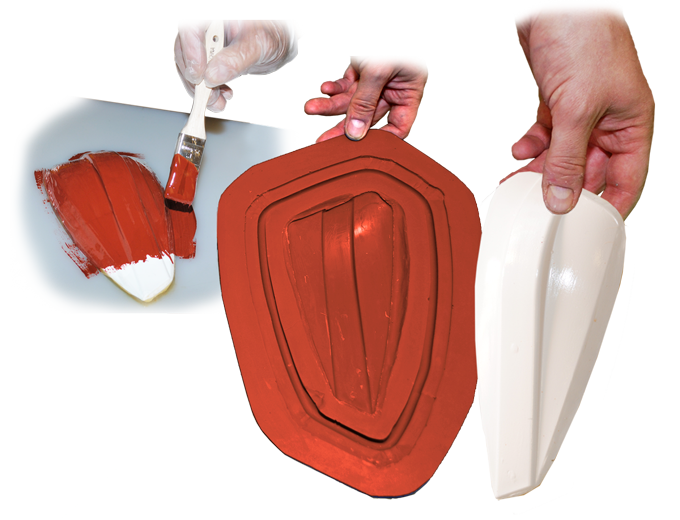

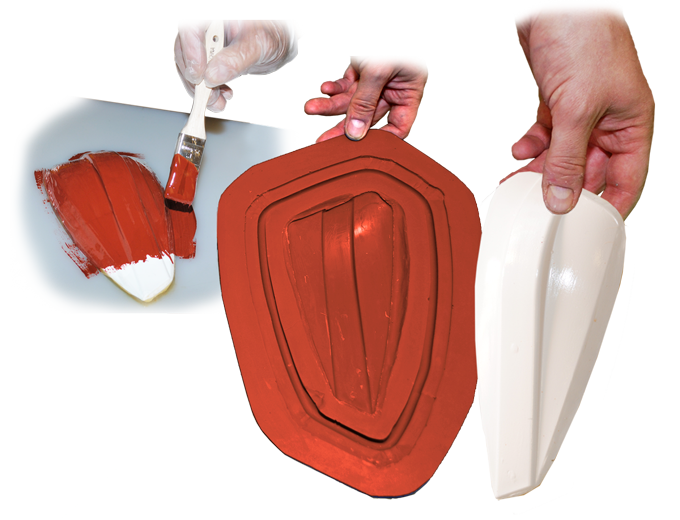

Fiberglass cloth is laminated behind the EpoxAcoat™ surface coat using EpoxAmite™ Laminating Epoxy to produce strong, lightweight tools that have excellent dimensional stability and surface finish. Free Form AIR™ Epoxy Putty can also be used in conjunction with EpoxAcoat™ and EpoxAmite™ to produce tooling to be used in hand lay up or vacuum bagging composite parts.

No Scale Necessary

No Scale Necessary

Brushable Application

Brushable Application

Making Rigid Masters and Props

Making Rigid Masters and Props

EpoxAcoat™ produces a rigid and paintable surface for making rigid Masters, Patterns, and Props that are dimensionally stable. EpoxAcoat™ RED or GRAY Surface Coat Epoxy can be laminated using layers of EpoxAmite™ Laminating Epoxy and fiberglass, Kevlar, or Carbon Fiber.

No Scale Necessary

No Scale Necessary

Tough and Strong

Tough and Strong

EpoxAcoat™ HT

High Temp Surface Coat Epoxy

EpoxAcoat™ HT

High Temp Surface Coat Epoxy

EpoxAcoat™ HT is a slightly thixotropic epoxy gel coat that offers high heat resistance (284°F / 140°C after Post Curing).

Gram Scale Required

Gram Scale Required

High Heat Resistance

High Heat Resistance

Technical and Buying Information

| Select a Product Below | Pot Life | Cure Time | Color |

|---|---|---|---|

| › EpoxAcoat™ RED | 20 mins | 16 hrs | Red |

| › EpoxAcoat™ GREY | 20 mins | 16 hrs | Grey |

| › EpoxAcoat™ WHITE | 20 mins | 16 hrs | White |

| › EpoxAcoat™ HT | 40 mins | 24 hrs | Dark Red |

| › EpoxAcoat™ NEUTRAL | 20 mins | 16 hrs | Neutral |

VIDEOS and GALLERIES

Step-by-Step How-To Articles

How To Create a High Temperature Tool Using EpoxAmite™ HT and EpoxAcoat™ HT

High temperature tooling resins play an important role in creating composite parts and are a low cost alternative to metal molds.

Resin Infusion: How To Fabricate a Composite Car Seat

This video demonstrates how vacuum resin infusion is used to make a car seat.