Metal Powder

For Real Metal Cold Castings

"Cold-Casting" is a term used to describe the process of mixing metal powder with a resin and applying the mixture into a mold. The finished casting gives the appearance and weight of solid metal. The metal cold-cast process is faster and much less expensive when compared with foundry casting of molten metal.

HIGHLIGHTS

Easy To Use

Easy To Use

Metal powder is mixed into Colormatch® resin until the mixture is thick and creamy. The mixture is then "slush-cast" or brushed onto the mold surface until the resin cures. The gel coat is then back-filled with straight resin, resin mixed with metal powder, resin mixed with steel weights or Foam‑iT!® rigid foam.

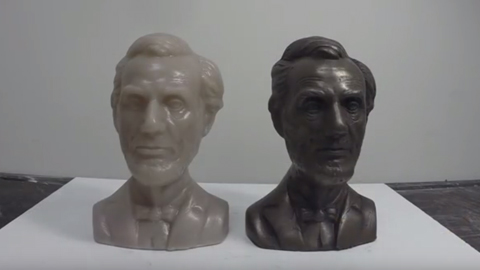

Aluminum

Aluminum

The mesh size of this aluminum powder is -200 vs. the -300 mesh for the other metal powders and gives a better cold cast effect compared with other mesh size powders that we tested. Polished castings are brighter vs. castings made using nickel/silver powder, which has more of an antique metal look.

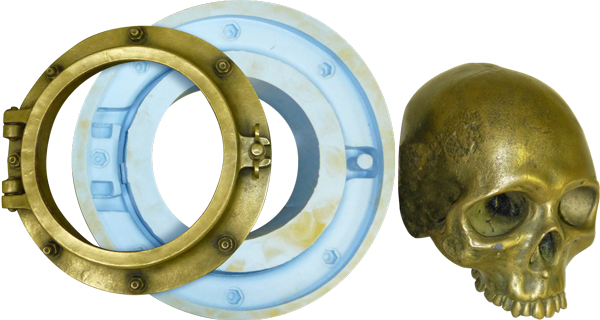

Brass

Brass

Perfect for producing castings with antique brass finishes. Polish the surface to bring out the shine of the metal powder. Afterwards, apply shoe polish to add depth and character to your pieces.

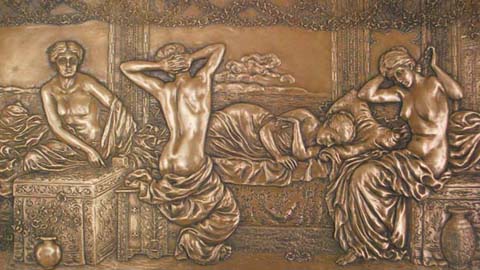

Bronze

Bronze

Polish your castings to produce a realistic cast bronze piece. Allow the metal in your castings to achieve a natural patina or accelerate the process with patina solutions.

Copper

Copper

With copper powder you can give your castings a bright, modern copper appearance great for low relief wall art. Burnish with black shoe polish and apply chemical patina for a stunning rustic look.

Nickel Silver

Nickel Silver

Castings made using nickel/silver powder can be polished to produce more of an antique metal look compared to the aluminum metal powder. When mixed with SmoothCast® ONYX plastic castings will have better heat resistance for applications where temperatures may exceed 200°F.

Technical and Buying Information

| Select a Product Below | Description |

|---|---|

| › Aluminum Metal Powder | Aluminum powder for metal cold casting effects |

| › Brass Metal Powder | Brass powder for metal cold casting effects |

| › Bronze Metal Powder | Bronze powder for metal cold casting effects |

| › Copper Metal Powder | Copper powder for metal cold casting effects |

| › Nickel Silver Metal Powder | Nickel silver powder for metal cold casting effects |

VIDEOS and GALLERIES

Step-by-Step How-To Articles

Turning a Clay Sculpture Into a Metal Cold Casting

Milo demonstrates how to make a silicone mold of a clay relief sculpture, then creates a metal cold casting.

How To Make a Metal Cold Casting With Smooth-Cast™ 325 Resin

The metal cold-casting process is faster and much less expensive compared with foundry casting of molten metal.

How To Make Metal Cold Cast Decorative Panels

Creating metal cold cast panels using Smooth Cast ONYX liquid plastic and bronze powder.

How To Replace a Brass Shower Door Handle

A "Cold Cast Brass" handle is molded and cast for a fraction of the cost of replacement.

How To Make a Resin Metal Cold Casting

Smooth-On fan Jon N. shows how he makes a mold for a real metal cold casting.

How To Make a Custom Cold Cast Aquarium Stand Using Urethane Resin

Use Smooth-Cast™ 325 resin and Bronze powder to make a nautical looking aquarium stand.

How To Make a Cold Cast Prop Wrench Using Real Metal Powders and Smooth-Cast™ 325

Learn How To Make a Metal Cold Cast Prop Wrench With Milo

Cold Casting a Bear Skull Using Urethane Resin and Nickel Silver Powder

Using Smooth-Cast 57D Milo demonstrates two techniques for casting his bear skull mold.

How To Make a Metal Cold Casting Using Matrix Dryve™ Polymer Gypsum

Learn how you can cold cast Matrix Dryve™ polymer gypsum

What Have Other People Done With These Products?

Metal Cold Casting Effects

Images showing different metal cold casting effects