Vacuum and Pressure Chambers

Create Bubble-Free Castings and Molds

Pressure Systems (pressure chambers and compressors) offer the optimal method for creating molds and resin castings that are truly bubble free.

Vacuum Systems (vacuum chambers and vacuum pumps that pull 29 inches of mercury) are used to remove the air from high viscosity materials like silicone rubber before pouring. They are also ideal for vacuum degassing liquid plastics for making bubble free castings.

HIGHLIGHTS

Pressure Chamber

Pressure Chamber

Versatile Unit for Pressure Casting Liquid Rubber and Liquid Plastics. Recommended Pressure for Pressure Casting is 60 psi. Pressure pot can be pressurized to 80 psi.

Inside Dimensions:

12.5" (31.75 cm) diameter opening X 15.25" (38.74 cm) Tall

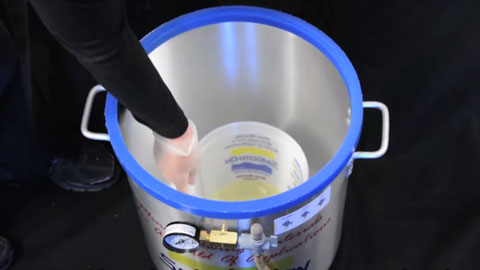

Vacuum Chamber

Vacuum Chamber

This easy to use vacuum chamber is tough aluminum and can accommodate up to a 5 gallon pail. The lid is made from shatter resistant acrylic and features a rubber gasket that creates a positive, air tight seal for maximum vacuum. Includes hose. Easy to read gauge let's you know if your vacuum pump is pulling the required 29" of mercury.

Inside Dimension:

14" (35.56 cm) diameter opening x 15" (38.1 cm) Tall.

Technical and Buying Information

| Select a Product Below | Description |

|---|---|

| › Pressure Chamber | Versatile Unit for Pressure Casting Liquid Rubber and Liquid Plastics. |

| › 2 Gallon Vacuum Chamber | For Vacuum Degassing Liquid Rubbers and Liquid Plastics |

| › 5 Gallon Vacuum Chamber | For Vacuum Degassing Liquid Rubbers and Liquid Plastics. |

VIDEOS and GALLERIES

Step-by-Step How-To Articles

How To Eliminate Bubbles In Resin Castings By Pressure Casting

Bubbles in clear castings can be removed by using a pressure casting technique, a shown in this tutorial video.

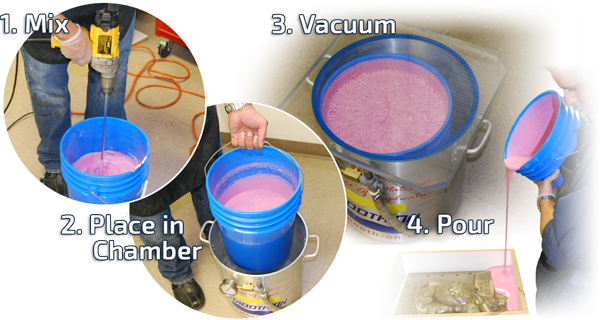

How To Reduce Bubbles In Castings By Vacuum Degassing

Clear resin performs best when the material is vacuumed before pouring, this tutorial video outlines the steps for degassing.

How To Vacuum Degas Silicone - Mold Max™ 30

How to vacuum silicone to eliminate entrapped air and remove bubbles from your finished mold or casting.

How To Vacuum Degas Urethane Resin - Smooth Cast™ 326

This video demonstrates vacuum degassing Smooth-Cast 326 to remove entrapped bubbles.

How To Eliminate Surface Bubbles in Your Casting

Milo demonstrates how you can use a pressure chamber to achieve bubble-free castings.