Rebound™ Series

Brushable Platinum Silicone Rubber

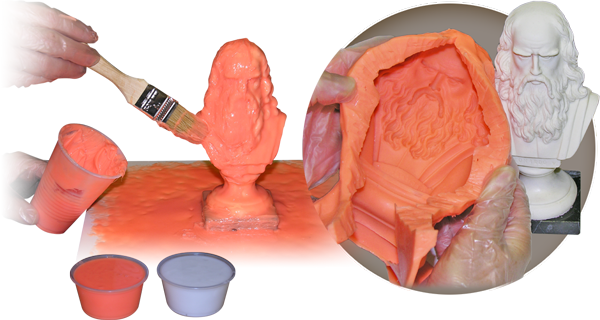

Rebound™ silicone rubbers are easy-to-use platinum-cure silicone rubbers which self-thicken for making brush-on molds of almost any model. Mixed 1A:1B by volume, Rebound™ can be applied with a brush or spatula to vertical surfaces without sagging and will cure with negligible shrinkage to a flexible rubber. Applications include reproducing sculpture, architectural restoration, making candle molds, etc.

HIGHLIGHTS

One to One Mix Ratio

One to One Mix Ratio

Mixed 1A:1B by volume (no scale necessary), Rebound™ can be applied with a brush or spatula to vertical surfaces without sagging and will cure with negligible shrinkage to a flexible rubber.

No Scale Necessary

No Scale Necessary

One to One Mix Ratio

One to One Mix Ratio

Extreme Strength

Extreme Strength

3 to 4 layers are all that is necessary to make a strong, durable production mold for casting wax, gypsum, concrete (GFRC) or resins (urethane, polyester, etc.). Because Rebound™ is a platinum silicone, it will last for many years in your mold library.

High Tear Strength

High Tear Strength

Brushable Application

Brushable Application

Technical and Buying Information

| Select a Product Below | Hardness | Elongation @ Break |

|---|---|---|

| › Rebound™ 25 | 25 A | 690 % |

| › Rebound™ 40 | 40 A | 324 % |

VIDEOS and GALLERIES

Step-by-Step How-To Articles

How To Choose The Right Method For Making a Rubber Mold

Discover the advantages and considerations behind block molds, brush-on molds, and cavity pour molds.

How to Make a Silicone Brush On Mold of a 3D Object

This tutorial shows how to create a Rebound™ 25 brush on silicone mold of a figurine

How To Turn a Sculpting Talent Into Cold, Hard Cash

“How Nice Ice” has provided ice sculptures for private parties, professional sports team banquets...

How To Make a Brush-On Mold of a 3D Hollow Model

This step by step gallery demonstrates how a challenging mold of a puma head will be made using Smooth-On's Rebound 25 brush-on silicone rubber...

How To Make a Brush-On Mold with a Lightweight Support

The following is a demonstration on how to make a mold of stone veneer using...

How To Create a Rebound™ 25 Mold to Cast a GFRC Banyan Tree

Pretecno engineer Jose Hormiga developed a way to bring an organic feel to some of the company's latest building projects.

How To Mold a Captain America Cosplay Helmet Using Rebound™ 25

Justin Jotso of Jester Productions and FX's replica Captain America helmet.

How To Cast a Concrete Fence Which Exhibits Detail Never Seen Before

Unique mold making process quickly generates 11,880 lightweight concrete panels...

How To Make Decorative GFRC Panels from a Jungle Tree Trunk

"Taller de Prefabricados" invited us to their facilities to film their mold making process

How To Make an Architectural Corbel Restoration Using Rebound 25

Watch how to make a mold of a corbel for an architectural restoration project in Brooklyn NY.

How To Make a Museum Quality Animal Reproduction

Learn how a sculpted reproduction of a rhinoceros torso was made

How to Make a Mold of a Rock for a Concrete Sink

Learn how to make a mold of a small boulder using Rebound 25 brush on silicone rubber.

Cosplay Tutorial: Iron Man Helmet - Part 1: How To Make a Silicone Glove Mold

How you can use Rebound 25 silicone rubber to make a mold of an Iron Man helmet.

How To Mold and Cast a Resin Sculpture - Ghost Rider

Learn how to mold and cast a backlit bust of the infamous Marvel character, Ghost Rider.

How To Mold a Prop Shield For Cosplay

Jon N. shows us how he creates a mold for his Thundercats shield.

Aquarium Decoration Tutorial - How To Make a Silicone Coral Stamp

This video shows how to create a silicone stamp from a piece of coral that can then be used to create detail.

How To Create a Mold and Casting of a Prop Shield

A plaster replica of an ancient Roman shield is used to make light weight and strong reproductions for display.

How To Make a Brush On Mold of an Antique Rifle

This tutorial shows how to make a two piece silicone mold of a historic firearm

How To Create Lightweight Theatrical Costume Armor

Andreas Moravec demonstrates a technique for creating theatrical armor using Rebound™ 25 silicone and Smooth Cast® resins

What Have Other People Done With These Products?

Daft Punk Helmet by Volpin Props

This helmet was the fruit of 17 months of work.

Jeff Birch's 'DESTRO' Mask Project

Jeff's research into moldmaking and casting materials went a long way towards making his project a huge success.

Sculptor Fran Volz Takes Rebound™ 25 to the Next Level

Fran Volz is an artist and mold maker living and working in the Chicago, IL area.

Randall Dana - Reviving Lost New York

Mr. Dana's passion is restoring gargoyles and other architectural ornamentation from 19th century buildings slated from demolition

Lost-Wax Artists Discover Rebound™ 25 Brush-On Silicone

Fonderie d’Art d’Inverness Inc is a Quebec corporation which portrays dynamism by using a mix of innovative methods and traditional techniques.

Arcana Workshop Brings to Life Xenomorph with Smooth-On Products

There is a new creature roaming the halls of Smooth-On. It stands seven feet tall and has razor sharp teeth!