Urethane Resin Accessories

Take Your Urethane Resin Further

Additives compatible with Smooth-On Urethane Resins Designed for altering and enhancing their characteristics and performance. Choose from a variety of colorants and fillers, cure accelerator, UV resistance enhancer, adhesive and more.

HIGHLIGHTS

Color Pigments and Tints

A Little Goes a Long Way

Color Pigments and Tints

A Little Goes a Long Way

- SO-Strong® colorants are highly concentrated, offer excellent dispersion and consistent color.

- UVO® Colorants are phthalate-free color pigments that resist ultra-violet light.

- Ignite® pigments are fluorescent colorants. Castings appear brighter and appear to glow under ultraviolet light.

Sun Devil™

UV Resistant Additive

Sun Devil™

UV Resistant Additive

A one component liquid additive that will slow color change and physical degradation due to UV exposure for many Smooth-On liquid urethane products.

UV Resistant

UV Resistant

Gram Scale Required

Gram Scale Required

XTEND-IT™

Dry Gas Blanket

XTEND-IT™

Dry Gas Blanket

Designed to extend the shelf life of unused moisture sensitive polyurethane products. Applying the XTEND-IT™ to the unused portion of a liquid polyurethane system will minimize residual moisture in the container and significantly extend the shelf life of what remains.

Great Value

Great Value

Cryptolyte™

UV Glow Additive

Cryptolyte™

UV Glow Additive

Causes cured Smooth-On silicone rubbers, urethane rubbers, plastics or foams to glow a bright blue under a focused ultra violet light source (blacklight). At low percentages it will not affect clarity or color of material and the glow effect will not be evident until the casting is illuminated by a UV light source.

No Scale Necessary

No Scale Necessary

SO-CURE™

Cure Accelerator

SO-CURE™

Cure Accelerator

Additive designed to accelerate the cure time of some Smooth-On urethane liquid plastic products without significantly affecting ultimate physical properties. This allows for much faster demolding of a part or casting from a mold.

Gram Scale Required

Gram Scale Required

Glow Worm™

Glow-In-The-Dark Powders

Glow Worm™

Glow-In-The-Dark Powders

Glow Worm™ phosphorescent powders can be added to Smooth-On liquid plastics, rubbers and foams to create castings that glow in the dark at least 10 times longer than other glow powders after being charged with light as recommended. Choose from either yellow/green or blue/green.

Cast Magic™ Powders

Create Amazing Casting Effects

Cast Magic™ Powders

Create Amazing Casting Effects

Easy way to add an endless variety of bright metallic, glitter & color effects to finished castings. With the Cast Magic™ System, you can create spectacular casting effects in a matter of minutes vs. hours or days for hand tooling and finishing.

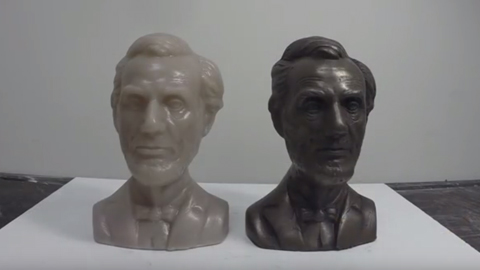

Metal Powders

For Real Metal Cold Castings

Metal Powders

For Real Metal Cold Castings

"Cold-Casting" is a term used to describe the process of mixing metal powder with a resin. The finished casting gives the appearance and weight of solid metal at a fraction of the cost. Choose from;

Quarry Tone™

Granite FX Fillers

Quarry Tone™

Granite FX Fillers

Specially blended powders that can be added to some Smooth-Cast™ liquid plastics or liquid rubbers to create realistic stone effects in finished castings. There are 10 granite effects powders to choose from, each with its own particle size and color.

URE-FIL™ Fillers

URE-FIL™ Fillers

- URE-FIL™ 3 Ceramic filler will give plastic castings a ceramic or porcelain-like finish.

- URE-FIL™ 5 Lightweight 'pecan flour' style filler for achieving a wood effect in casting plastics.

- URE-FIL™ 7 Provides dimensional stability, economy & improved flame resistance to liquid plastics.

- URE-FIL™ 11 can be added to thicken liquid plastics for brush-on applications.

- URE-FIL™ 15 Micro-balloons that can be added to liquid plastics to create very light weight castings.

- URE-FIL™ 17 and 19 aluminum pellets improve thermal conductivity, dimensional stability, reduce shrinkage.

Doxy 5™

Urethane Resin Degassing Agent

Doxy 5™

Urethane Resin Degassing Agent

Will aid in vacuum degassing urethane plastics and is effective in situations where vacuum equipment may not be pulling the required 29 inches of mercury necessary to fully vacuum material.

No Scale Necessary

No Scale Necessary

Technical and Buying Information

| Select a Product Below | Description |

|---|---|

| › SO-Strong™ | Colorants for Urethane Rubber, Resin and Foam |

| › Ignite™ | Fluorescent Colorants For Liquid Rubber, Plastic and Foam |

| › UVO™ | UV Resistant Colorants for Epoxy and Urethane. |

| › SO-CURE™ | Cure Accelerator |

| › Sun Devil™ | UV Resistant Additive |

| › XTEND-IT™ | Dry Gas Blanket |

| › Cryptolyte™ | UV Glow Additive for Urethanes and Silicones |

| › Glow Worm™ | Long Lasting Glow-in-the-Dark Powder |

| › Quarry Tone™ | Granite FX Fillers |

| › Cast Magic™ | Create Amazing Casting Effects |

| › Doxy 5™ | Vacuum Degassing Agent |

| › Bronze Metal Powder | Bronze powder for metal cold casting effects |

| › Brass Metal Powder | Brass powder for metal cold casting effects |

| › Copper Metal Powder | Copper powder for metal cold casting effects |

| › Nickel Silver Metal Powder | Nickel silver powder for metal cold casting effects |

| › Aluminum Metal Powder | Aluminum powder for metal cold casting effects |

| › URE-FIL™ 3 | Ceramic Filler to Reduce Cost of Casting |

| › URE-FIL™ 5 | Filler for Creating a Wood-Grain Effect |

| › URE-FIL™ 7 | Urethane Filler for Dimensional Stability |

| › URE-FIL™ 11 | Fiber Filler for Urethane and Silicone |

| › URE-FIL™ 15 | Micro-Balloons to Reduce Casting Weight |

| › URE-FIL™ 17 | Aluminum Pellet Filler (400 micron) |

| › URE-FIL™ 19 | Aluminum Pellet Filler (1200 micron) |

VIDEOS and GALLERIES

Step-by-Step How-To Articles

How To Make a Metal Cold Casting With Smooth-Cast™ 325 Resin

The metal cold-casting process is faster and much less expensive compared with foundry casting of molten metal.

How To Use Glow Worm® to Make a Glow In The Dark Casting

How to best use Glow Worm phosphorescent powder to create a resin casting which will glow in the dark for up to 10 hours.

How To Make a Resin Metal Cold Casting

Smooth-On fan Jon N. shows how he makes a mold for a real metal cold casting.

How To Make Finger Corals Using Smooth Cast™ Plastic

You can create perfect copies of any piece of original coral using mold rubber and liquid plastic.

How To Make a Foam Prop Hammer

Learn to make foam props using a unique method for splitting a two part mold

Making a Master Model Using Smooth-Cast 310 and URE-FIL 7

In this how-to video, Milo shows how to make a master model which is used to make numerous flexible rubber molds.