XTC-3D™

High Performance 3D Print Coating

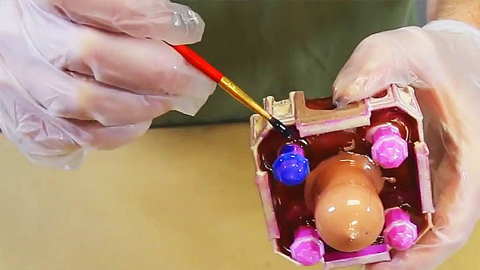

Protective coating for smoothing and finishing 3D printed parts that does not melt plastic. XTC‑3D™ fills in 3D print striations and creates a smooth, high gloss finish. The need to post finish is almost eliminated. XTC‑3D™ can be applied to both SLA and SLS prints. It works with PLA, ABS, Laywoo, Powder Printed Parts and other rigid media such as EPS, EPDM and urethane foam as well as wood, plaster, fabric, cardboard and paper.

HIGHLIGHTS

Coat any 3D Print Surface

Coat any 3D Print Surface

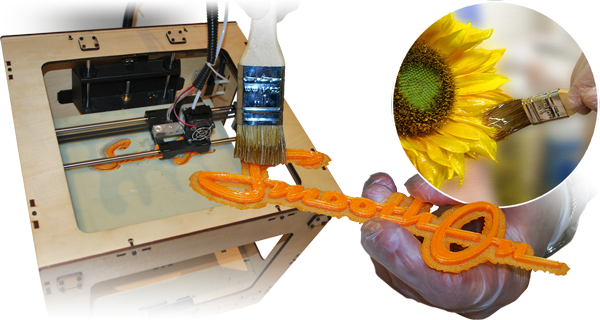

XTC-3D™ does not melt plastic. Two liquids are mixed together and brushed onto any 3D print, fabric, wood, and more. Coating self-levels and wets out uniformly without leaving brush strokes.

No Scale Necessary

No Scale Necessary

Easy to Brush

Easy to Brush

Inexpensive to Use

Inexpensive to Use

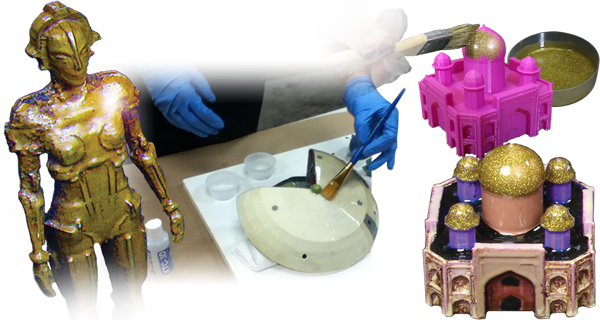

1 oz covers 100+ square inches. 90% Time & Labor Savings means the need to post finish is almost eliminated. XTC‑3D™ can be mixed with metal powders, SO-Strong™ tints, and Ignite™ or UVO™ pigments making adding colors and metal effects easy.

Easy to Color

Easy to Color

Excellent Value

Excellent Value

Technical and Buying Information

| Select a Product Below | Description |

|---|---|

| › XTC-3D™ | High Performance 3D Print Coating |

VIDEOS and GALLERIES

Step-by-Step How-To Articles

How to Make a Free-Form Concrete Sink

Watch how to make an elegant shallow free-form concrete sink from start to finish

How To Make a Silicone Mold of a 3D Printed Part and Casting a Detailed Resin Training Skeleton

Watch how a medical training model is cast in resin.

How To Make a Glow Effect in Wood With XTC 3D and Glow Worm

Create an amazing glow effect in a real wood shelf

How To Add Color Effects To a 3D Printed Part Using XTC-3D™

This video demonstrates how to use XTC-3D epoxy coating to smooth and apply color to a 3D printed architectural model.

How To Coat a Flower With Resin

Watch as Jara coats a silk flower with XTC-3D epoxy resin to create a long-lasting glossy display.

How To Smooth the Surface of a 3D Printed Model Using XTC-3D™

In this video, XTC-3D® Epoxy is used to coat a 3D piece printed in PLA.

Quickly Adding a Metallic Finish to a 3D Print

This video shows how to make a 3D printed PLA object look like real metal using XTC-3D® epoxy.

Prototyping a Durable Conveyor Belt Cleaner

From a PLA 3D printed prototype, learn how to make a durable belt cleaner out of industrial urethane rubber

How To Repair a Skimboard Using XTC-3D™ Epoxy

In this how-to tutorial video we show how XTC-3D® epoxy resin can be used to repair a skimboard.

Making a Platinum Silicone Mold of an SLA Printed UV-Cure Model

Learn how model makers create rubber molds and multiple castings of 3-D prints made with SLA.