Crystal Clear™ 222 - Mercury Free

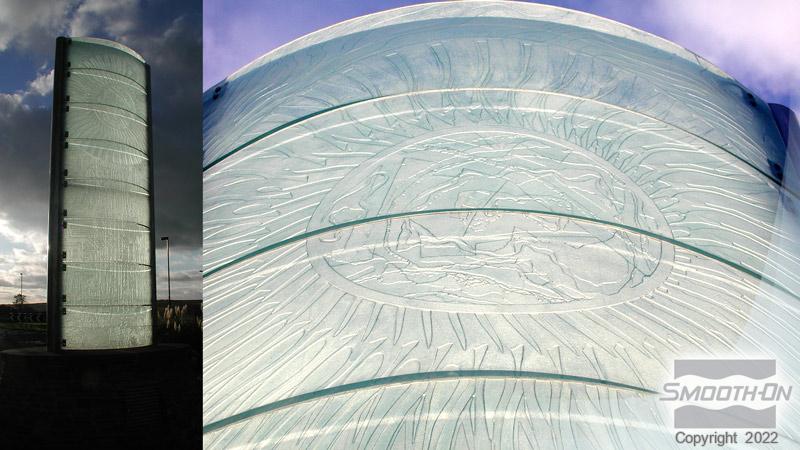

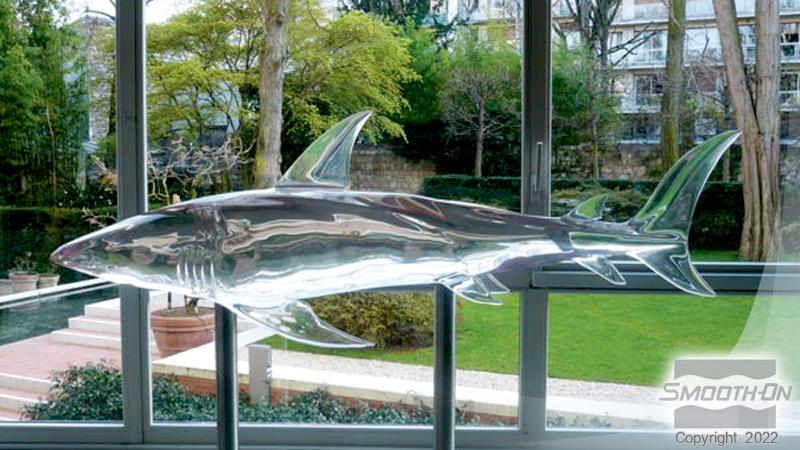

Crystal Clear™ 222 is a mercury-free, phthalate-free water white clear resin made specifically for applications that require optical clarity. Low viscosity ensures easy mixing and pouring. Crystal Clear™ 222 cures with negligible shrinkage. Cured castings are UV resistant and are not brittle. Vibrant colors and color effects are achieved by adding So‑Strong™, UVO™ or Ignite™ colorants. Applications include encapsulation, making prototype models, lenses, sculpture reproductions, decorative cast pieces, jewelry, prototype models, special effects and props.

REQUIRED: Castings must be made under pressure using an appropriate pressure vessel (60 psi / 4.14 bar).

CAUTION: NOT FOR HOME USE. THIS PRODUCT IS FOR INDUSTRIAL USE ONLY. With adequate local exhaust ventilation, respiratory protection is not normally required when using this product. Where risk assessment shows air-purifying respirators are appropriate, follow OSHA respirator regulations and European Standards EN 141, 143 and 371. Protective clothing (gloves and long sleeves) is required to minimize the risk of dermal sensitization. If breathing is affected or a dermal rash develops, immediately cease using this product and seek medical attention. Read SDS before using.

Features

Cured castings are:

- UV Resistant (resists yellowing due to ultra-violet light exposure)

- Not brittle

- Mecury-Free

Vibrant colors and color effects are achieved by adding pigment dispersions. Applications include encapsulation, making prototype models, lenses, sculpture reproductions, decorative cast pieces, jewelry, special effects and props.

› Click here for more Crystal Clear™ resin products.

Instructions

Instructions

Safety - Store and use at room temperature (73°F/23°C). These products have a limited shelf life and should be used as soon as possible. Environmental humidity should be as low as possible. Good room size ventilation is essential. Wear safety glasses, long sleeves and rubber gloves to minimize contamination risk. Wearing a NIOSH approved respirator will minimize inhalation of residual fumes.

Selecting a Mold Rubber - Pour into a urethane rubber mold (Vytaflex™ urethane – release agent required), tin cured silicone mold (Mold Max™ silicone) or Mold Star™ 15, 16 or 30 platinum cured silicone (not Mold Star™ T series). Do not use other rubber mold products.

If using Mold Max™ silicone; to prevent cure inhibition, post-cure newly cured silicone mold for 8 hours at 150°F/60°C and let cool prior to casting resin. If you are unsure about surface compatibility, a small scale trial casting should be made.

Casting Thickness & Cure Time - The cure time and ultimate shrinkage of Crystal Clear™ 222 will vary depending on mass concentration, thickness of the casting, mold configuration, etc. For example, a 200 gram mass of Crystal Clear™ 222 will cure faster if left to cure in a conical vessel (cup) versus a casting dispersed as a thin sheet measuring 3 centimeters square by 1 mm thick. This is due to the heat generated by the concentration of material in the cup versus heat that is dissipated from the sheet casting.

Castings will resist yellowing when exposed to UV, but may darken over time.

Crystal Clear™ 222 is intended for casting thicknesses up to 2” (5.08 cm.) at a casting weight maximum of 10 lbs. (4.54 kgs.) Castings greater than 2” (5.08 cm.) thick with a casting weight over 10 lbs. (4.54 kgs.) should be layer cast.

Pre-heat the rubber mold at 150°F / 65°C for 4 hours before mixing & pouring Crystal Clear™ 222. This will minimize the chances that cured castings will exhibit casting phenomenon such as fish-eyeing, suck back, corner rounding, large bubbles, etc.

Liquid urethanes are moisture sensitive and will absorb atmospheric moisture. Mixing tools and containers should be clean and made of metal or plastic. Materials should be stored and used in a warm environment (73°F/23°C).

Pre-Mixing - Stir or shake Part B thoroughly every time before dispensing.

Measuring - Materials should be stored and used at room temperature (73°F/ 23°C). The proper mixing ratio is 100A:75B by weight. You must use an accurate digital gram scale to weigh Parts A and B properly. Do not use an analog scale or attempt to measure components by volume. Dispense the required amount of Part A into a mixing container. Weigh out the appropriate amount of Part B and combine with Part A.

Mixing - Mix SLOWLY, but thoroughly, for at least 90 seconds making sure that you scrape the sides and bottom of your container several times. If coloring or filling Crystal Clear™ 222, add filler or pigment dispersion to Part B and mix thoroughly before adding Part A.

Pouring - If casting Crystal Clear™ 222 into a rubber mold, pour mixture in a single spot at the lowest point of the mold. If encapsulating an object, do not pour the mixture directly over the object. Let the mixture seek its level. A uniform flow will help minimize entrapped air. Castings must be made under pressure: After pouring the mixed resin, the entire casting assembly (mold, dam structure, etc.) must be placed in a pressure chamber and subjected to 60 PSI (4.14 bar) air pressure for at least 16 hours at room temperature prior to post curing.

Room Temperature Cure - Followed By Post Cure - Allow material to cure for at least 16 hours at room temperature (73°F / 23° C). Place entire mold structure in an oven and cure at 150°F / 65°C for 4 hours, followed by 4 hours at 212°F / 100°C. Allow casting or part to cool to room temperature before demolding.

Because no two applications are quite the same, a small test application to determine suitability for your project is recommended if performance of this material is in question.