EpoxAcast™ 670 HT

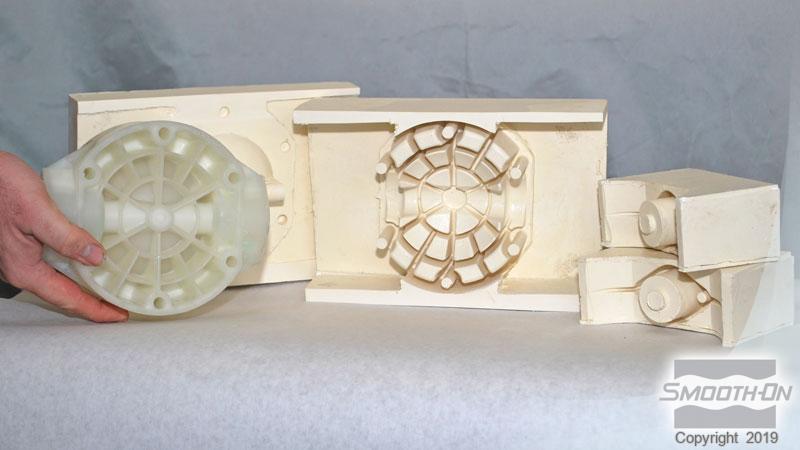

EpoxAcast™ 670 HT is an easy-to-use epoxy casting compound that offers high heat resistance up to 350°F/177°C (post cure required). EpoxAcast™ 670 HT is ideal for making vacuum forming and thermoforming molds, creating foundry patterns, forming dies & fixtures, hard rollers, industrial parts and high impact tools. EpoxAcast™ 670 HT is also suitable for encapsulation applications or for use as a high temperature epoxy for bonding a variety of surfaces.

Features

EpoxAcast™ 670 HT features a relatively low viscosity that ensures minimal bubble entrapment. EpoxAcast™ 670 HT also offers an extra long working time of 3 hours. Castings cure with negligible shrinkage and are very hard, very strong and heat resistant.

› Click here for more EpoxAcast™ resin products.

Instructions

Preparation– Avoid breathing fumes - use in a well ventilated area at minimum. NIOSH approved respirator is recommended. Wear safety glasses, long sleeves and rubber gloves to minimize skin contact.

Materials should be stored and used in a room temperature environment (73°F/23°C). Elevated temperatures will reduce pot life. EpoxAcast™ 670 HT Resin and Hardener must be properly measured and thoroughly mixed to achieve full, highstrength, solid-cure properties. Mixing containers should have straight sides and a flat bottom. Mixing sticks should be flat and stiff with defined edges for scraping the sides and bottom of your mixing container. Because no two applications are quite the same, a small test application to determine suitability for your project is recommended if performance of this material is in question.

Applying a Release Agent – For releasing epoxy from nonporous surfaces such as resin, metal, glass etc., use Ease Release™ 200 or 205 (available from Smooth-On) to prevent adhesion.

IMPORTANT: To ensure thorough coverage, lightly brush the release agent with a soft brush over all surfaces of the mold or model. Follow with a light mist coating and let the release agent dry for 30 minutes.

Pre-mix Part A Thoroughly - Separation may have occurred in transit or storage. Pre-mix for 2 minutes prior to dispensing to a uniform consistency using a straight edge paddle (paint stirrer) or turbo mixer (drill attachment).

Measuring / Dispensing – Stir Part B thoroughly before dispensing. Accurate measurement by weight is required for the material to cure properly and develop full physical properties. Dispense Parts A and B in proper proportions into clean plastic, metal or wax-free paper containers. You must use an accurate digital gram scale to weigh Parts A and B properly. Do not use an analog scale or attempt to measure components by volume.

Adding Color & Fillers - EpoxAcast™ 670 HT can be colored with UVO™ or IGNITE™ colorants (from Smooth-On). Pre-mix colorant with Part A thoroughly and then add Part B. A variety of dry fillers can also be added. Pre-mix dry filler with Part A before adding Part B.

Mixing – Be sure mixing utensils are clean and free of any potential contaminants such as dirt, dust or grease. Mix Parts A and B thoroughly for at least 3 minutes with a square edged mixing stick. Be aggressive and scrape sides and bottom of mixing container several times. Use the square edge of mixing stick to bring material off of the sides of container and blend. If using a drill mixer, follow with hand mixing as directed above to ensure thorough mixing.

Vacuuming - EpoxAcast™ 670 HT is low in viscosity compared to other epoxy casting systems and does not require vacuum degassing. If you choose to vacuum the material, subject mixture to 29 h.i.g. mercury in a vacuum chamber until mixture rises, breaks and falls. Allow for 5 times volume expansion in mixing container.

Lowering Viscosity - Epic™ Epoxy Thinner is a clear, water-like liquid that will lower the viscosity of some Smooth-On casting and laminating epoxies. Epic™ is not a solvent and can be added in different proportions to improve flow-ability to make it easier to mix and pour or laminate. Epic™ will also aid in reducing bubble entrapment.

Pouring – If casting EpoxAcast™ 670 HT into a rubber mold, pour mixture in a single spot at the lowest point of the mold. Let the mixture seek its own level. A uniform flow will help minimize entrapped air.

If making vacuum forming molds, it is best to use piano wire (15/1000 inch gauge) to make vacuum holes.

Cure Time - Refer to specified Cure Times in Handling Properties section. Cured material will be hard and unable to penetrate with a finger nail. Cured epoxy can now be dry sanded. If machining or sanding, wear NIOSH approved mask to prevent inhalation of particles. Pot life and cure time values are dependent on mass and mold configuration, as epoxies are mass-sensitive.

Heat Curing - For best results, EpoxAcast™ 670 HT should be heat cured in a dedicated industrial oven. Cure at 175° F / 80° C for two hours, followed by three hours at 300° F / 150° C. Allow material to cool to room temperature before use.

Painting – Cured EpoxAcast™ 670 HT can be painted or primed and then painted with acrylic enamel paints. Let paint fully dry before putting part into service.

Removing Epoxy – Uncured / Non-curing epoxy - Scrape as much material as possible from the surface using a scraper. Clean the residue with E-POX-EE KLEENER™ available from Smooth-On, lacquer thinner, acetone or alcohol. Follow safety warnings pertaining to solvents and provide adequate ventilation.