Ignite™

The Ignite™ line of liquid fluorescent colorants is compatible with Smooth-On urethane rubbers, plastics, foams (rigid and flexible) and epoxy resins. The fluorescent or “glow” effect is maximized under ultra-violet light or “black light.” The most dramatic color effect is realized when an Ignite™ colorant is used with a clear or translucent rubber (such as Clear Flex™ 50) or plastic (such as Smooth-Cast™ 325 or EpoxAcast™ 690).

What makes castings made with Ignite™ colorants appear to glow? When you add Ignite™ fluorescent color to a urethane material, more ultraviolet light from the cured material is visible to your eye vs. castings made with SO Strong™ colorants. Castings appear brighter in ambient light and appear to glow under UV light (black light).

Instructions

To get you started, we offer the following colorant loading levels. Results may vary.

By Weight Using A Gram Scale: Add Ignite™ colorant at a ratio of between 0.5% - 1.5% of the total weight (Parts A + B mixed) of the material being cast. 1% pigment yields the best results. Adding more than 1.5% by weight offers no benefit and is a waste of the colorant. Too much colorant may cause cure inhibition.

By Volume Measured In Drops: Add 30 drops of Ignite™ per 3 oz (88 ml) of mixed urethane material. If using a translucent material (like Smooth-Cast 325 or EpoxAcast™ 690) you can use 15 drops to maintain translucency of the material.

Pre-Mix Before Using: Ignite™ colorants are pigment dispersions and may separate over time. They must be thoroughly pre-mixed in the container before using with a liquid urethane product.

Directions For Use: After dispensing the required amount of urethane material Parts A and B into measuring containers, add colorant to Part B and mix thoroughly. Combine Parts A and B into a mixing container and mix as directed by the urethane product technical bulletin. Blending Colors - You can combine different colors on a palette to create a custom color before adding to liquid urethane product as directed above.

There are no issues when using this product with urethane rubbers, plastics and foams or tin-catalyzed silicones. However…Ignite™ pigments will drastically thicken platinum silicone rubber. Adding Ignite™ colorants to a Smooth-On platinum cure silicone such as Dragon Skin™ will make the silicone notably thicker, thereby affecting its ability to be vacuum degassed. Recommended loading maximum is 1% Ignite pigment by weight. An option for using Ignite™ colorants with a platinum silicone may be to use pigmented material as paint for brushing on to an existing platinum silicone casting or appliance. You can use Ignite™ colorants with our Psycho Paint™ system. For fluorescent effects in platinum silicones, we recommend Silc-Pig™ ELECTRIC fluorescent silicone pigments.

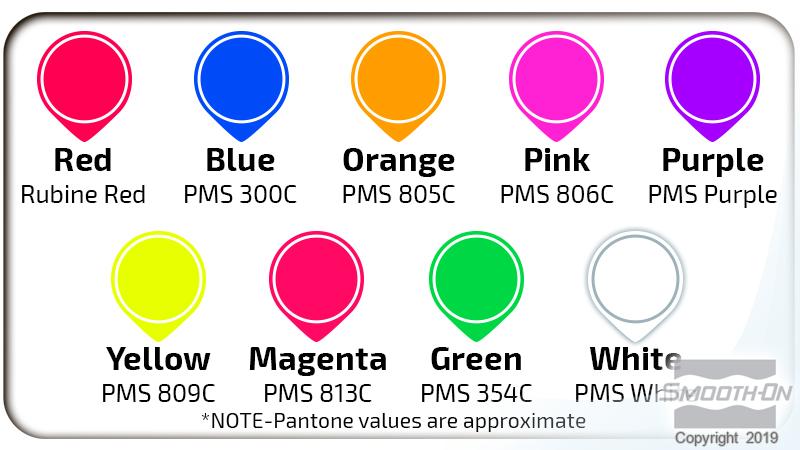

Smooth-On offers this color guide as a general reference only and assumes no responsibility for color accuracy or matching. Results will vary from one material to another. The end user is solely responsible for determining color suitability and accuracy. Small scale testing is recommended.

Looking for a clear fluorescent additive? Cryptolyte™ is a clear additive that can be added to urethane or silicone materials that will cause cured material to glow a bright blue when exposed to UV light (black light).

Related Categories: Urethane Rubber, Urethane Resins, Urethane Expanding Foams, Epoxy Casting and Laminating Resins, Epoxy and Urethane Coatings, Colorants, Paints & Fillers

Related Series: Ignite™ – Fluorescent Color Pigments, Urethane Resin Accessories – Take Your Urethane Resin Further, Urethane Rubber Accessories – Take Your Urethane Rubber Further, Epoxy Accessories – You Can Do Even More, Expanding Foam Accessories

How-To Articles

How To Make Finger Corals Using Smooth Cast™ Plastic

You can create perfect copies of any piece of original coral using mold rubber and liquid plastic.