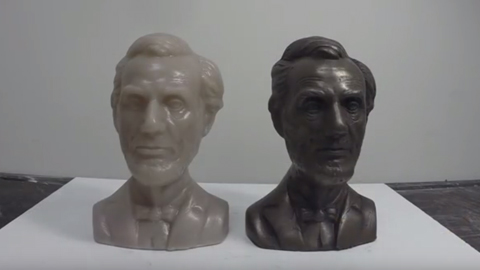

Nickel Silver Metal Powder

"Cold-Casting" is a term used to describe the process of mixing metal powder with a resin and applying the mixture into a mold. The finished casting gives the appearance and weight of solid metal. The metal cold-cast process is faster and much less expensive when compared with foundry casting of molten metal.

To make a metal cold-casting, metal powder is mixed into Smooth-Cast™ 325 Colormatch™ resin, duoMatrix™ NEO, or Matrix Dryve™ until the mixture is thick and creamy. The mixture is then "slush-cast" or brushed onto the mold surface until the material cures. The gel coat is then back-filled with straight resin, resin mixed with metal powder, resin mixed with lead shot or Foam-iT!™ rigid foam. Smooth-On offers metal powders that can be added to our liquid plastics to create cold cast metal castings.

Powders include bronze, brass, copper, aluminum and nickel/silver (for a pewter-like effect).

How-To Articles

How To Make a Metal Cold Casting Using Matrix Dryve™ Polymer Gypsum

Learn how you can cold cast Matrix Dryve™ polymer gypsum

Cold Casting a Bear Skull Using Urethane Resin and Nickel Silver Powder

Using Smooth-Cast 57D Milo demonstrates two techniques for casting his bear skull mold.

How To Make a Cold Cast Prop Wrench Using Real Metal Powders and Smooth-Cast™ 325

Learn How To Make a Metal Cold Cast Prop Wrench With Milo

How To Make a Foam Prop Hammer

Learn to make foam props using a unique method for splitting a two part mold

How To Make a Custom Cold Cast Aquarium Stand Using Urethane Resin

Use Smooth-Cast™ 325 resin and Bronze powder to make a nautical looking aquarium stand.

How To Make a Resin Metal Cold Casting

Smooth-On fan Jon N. shows how he makes a mold for a real metal cold casting.

How To Make a Metal Cold Casting Using duoMatrix™ NEO

We demonstrate how to create a metal cold casting using the duoMatrix™ NEO polymerized gypsum system.

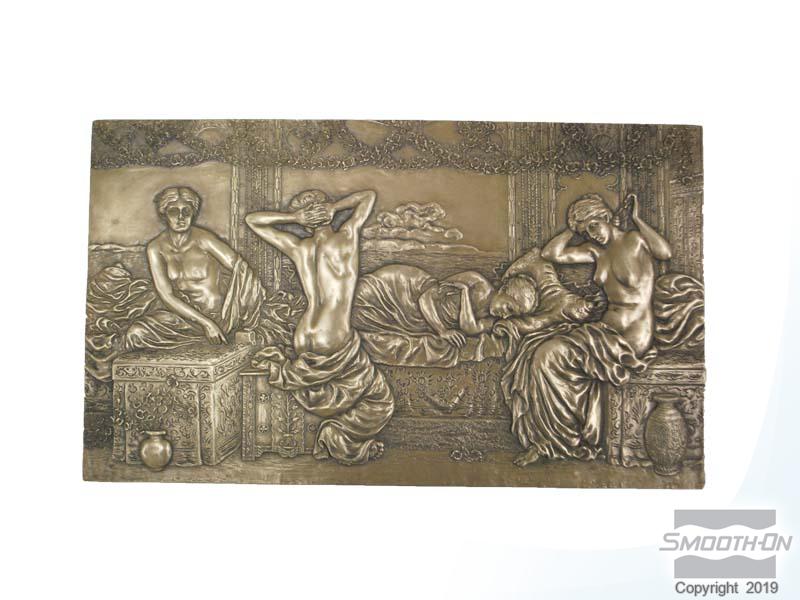

How To Make Metal Cold Cast Decorative Panels

Creating metal cold cast panels using Smooth Cast ONYX liquid plastic and bronze powder.

How To Make a Metal Cold Casting With Smooth-Cast™ 325 Resin

The metal cold-casting process is faster and much less expensive compared with foundry casting of molten metal.

Lifecasting Tutorial: Partially Clothed Female Torso Mold and Bronze Cold Casting

In this video tutorial, we show how to make a mold of a female torso using Body Double Lifecasting Silicone