Silc Pig™ Electric

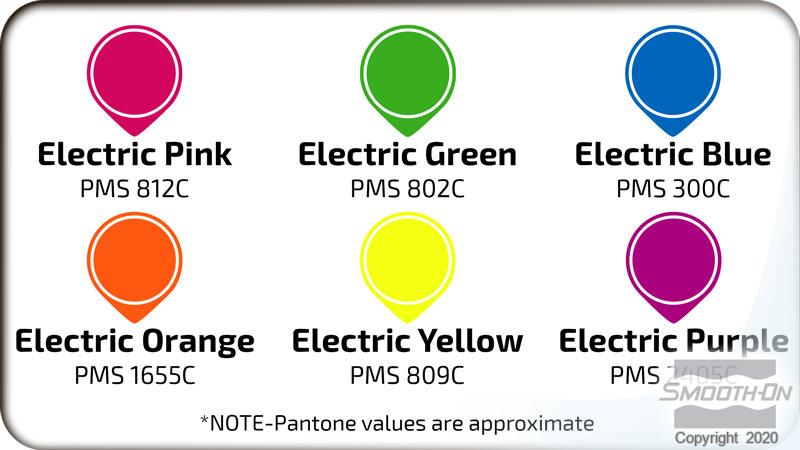

Silc Pig™ Electric Fluorescent Silicone Pigments are used for coloring tin-cure silicone rubber compounds such as Mold Max™ translucent ‘T’ Series products and platinum-cure silicones such as Dragon Skin™ and Ecoflex™ rubbers. Silc Pig™ Electric Fluorescent Pigments also work well with Smooth-On’s skin effects systems such as Psycho Paint™ and Skin Tite™. The fluorescent or “glow” effect is maximized under ultra-violet light or “black light.” The most dramatic color effect is realized when a Silc Pig™ Electric Fluorescent Pigment is used with a clear or translucent silicone.

What makes castings made with Silc Pig™ Electric Fluorescent Pigments appear to glow? When you add Silc Pig™ Electric Fluorescent Pigments to a silicone, more ultraviolet light from the cured material is visible to your eye vs. castings made with standard Silc-Pig™ pigments. Castings appear brighter in ambient light and appear to glow under UV light (black light).

Features

- Silc Pig™ Electric Fluorescent Silicone Pigments are concentrated, so a little goes a long way when coloring Smooth-On silicone products.

- Custom colors are possible by blending different Silc Pig™ Electric Fluorescent colors.

- Silc Pig™ Electric Fluorescent Silicone Pigments are skin safe and certified by an independent laboratory.

Instructions

Custom colors are possible by blending different Silc Pig™ Electric Fluorescent Pigment colors. Attaining just the right color for your application may require trial and error testing. Small scale testing is recommended before using substantial amounts of material for any project.

Silc Pig™ Electric Fluorescent Pigments are concentrated, so a little goes a long way when coloring Smooth-On silicone products. Recommended loading range is .001% to 3% of total silicone system weight. Do not overload silicone rubber with Silc Pig™ Electric Fluorescent Pigments or cure inhibition may occur. Pre-mix Silc Pig™ Electric Fluorescent Pigment in container thoroughly before dispensing as settling may have occurred. Add Silc Pig™ Electric Fluorescent Pigment to the Part A side of the silicone rubber system and mix well before adding Part B.

For directions on using Dragon Skin™ or other Smooth-On silicone rubbers, consult the technical bulletin for that product.