Solaris™

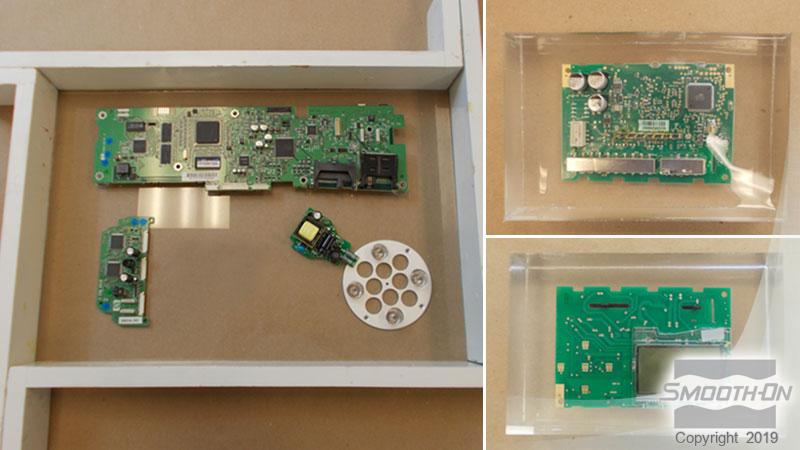

Solaris™ is a low viscosity, clear and colorless liquid platinum cure silicone rubber compound designed for use in protecting of electronic components and other assemblies. It will protect components against shock, vibration, moisture, ozone, dust, chemicals and other environmental hazards.

Features

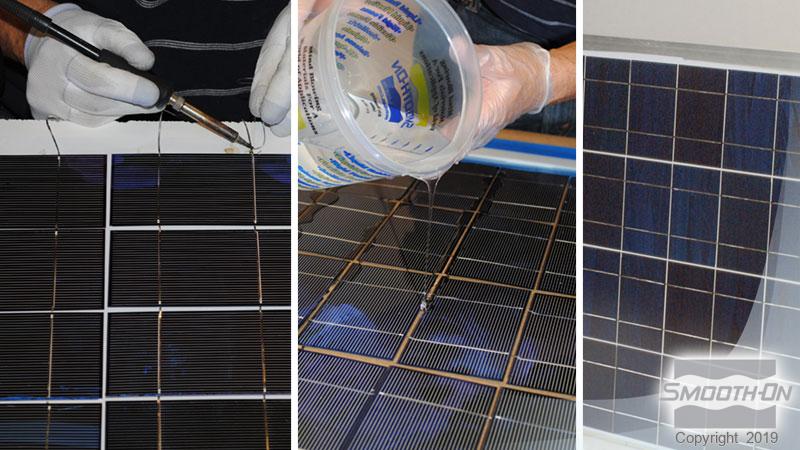

The optical clarity of Solaris™ makes it suitable for potting solar cells for maximum light transmission or electronic assemblies where component identification is necessary. For best results, use with Solaris™ Bonding Primer™.

- Ultra-transparent Solaris™ provides excellent UV resistance yet allows maximum transmission of light.

- Solaris™ features a low viscosity which allows easy flow in and around complex shapes, providing excellent electrical insulation and shock resistance.

- Solaris™ will cure in deep sections or enclosed assemblies without exotherm.

- Solaris™ encapsulant contains no solvents and has no VOC’s.

- The hydrolytic stability of Solaris™ makes it suitable in high humidity environments and at elevated temperatures.

Instructions

Safety – Use in a properly ventilated area (“room size” ventilation). Wear safety glasses, long sleeves and rubber gloves to minimize contamination risk. Wear vinyl gloves only. Latex gloves will inhibit the cure of the rubber.

Store and use material at room temperature (73°F/23°C). Storing material at warmer temperatures will reduce the usable shelf life of unused material. These products have a limited shelf life and should be used as soon as possible.

FOR MAXIMUM ADHESION TO GLASS - USE SOLARIS™ BONDING PRIMER...

All glass surfaces must be clean before applying Solaris™ Bonding Primer™

Glass surface preparation:

Step 1- Wipe glass surfaces using Isopropyl Alcohol applied with lintfree paper towels. Let dry for 10 minutes.

Step 2 - Wipe the glass surfaces with ammonia-based glass cleaner applied with lint-free paper towels. Let dry for 10 minutes.

Note: Do not touch glass surface after cleaning.

When glass surface is clean, apply one coat of Solaris™ Bonding Primer™ using a clean, dry paint brush and let dry for 10 minutes.

A hazy film will form on the glass surface. Wipe away film using a lintfree cloth until surface is clear.

Apply a second coat of Solaris™ Bonding Primer™, let dry for 10 minutes and wipe surface until clear.

You are now ready to apply the Solaris™ Silicone Encapsulant to the prepared glass surface.

CURE INHIBITION...

Solaris™ silicone rubber compound will cure in contact with most clean, dry surfaces. However, certain materials, such as butyl and chlorinated rubber, materials containing sulfur, amines, and non-platinum RTV silicone rubber compounds will cause cure inhibition and rubber will not cure.

If compatibility between the rubber and the surface is in question, a smallscale test is recommended. Inhibition has occurred if the rubber is gummy or uncured after the recommended cure time has passed.

Because no two applications are quite the same, a small test application to determine suitability for your project is recommended if performance of this material is in question.

MEASURING & MIXING...

Before you begin, pre-mix Part B thoroughly. After dispensing required amounts of Parts A and B into mixing container (1A:1B by volume or weight), mix thoroughly for 3 minutes making sure that you scrape the sides and bottom of the mixing container several times. After mixing thoroughly for 3 minutes, empty the contents of your mixing container into a second clean mixing container and mix again for another 2 to 3 minutes before pouring. This technique is your best bet for successful mixing.

For best results, vacuum degassing is recommended to help eliminate any entrapped air. Subject mixture to 29” of mercury in a vacuum chamber until mixture rises, breaks and falls. Allow for 3 to 4 times volume expansion in mixing container. Be aware of pot life so that material does not set up in mixing container.

Pouring - For best results, pour your mixture in a single spot at the lowest point of the containment field. Let the rubber seek its own level. A uniform flow will help minimize entrapped air.

Curing - Allow rubber to cure for 24 hours at room temperature (73°F/23°C) before demolding. Do not cure rubber where temperature is less than 65°F/18°C.