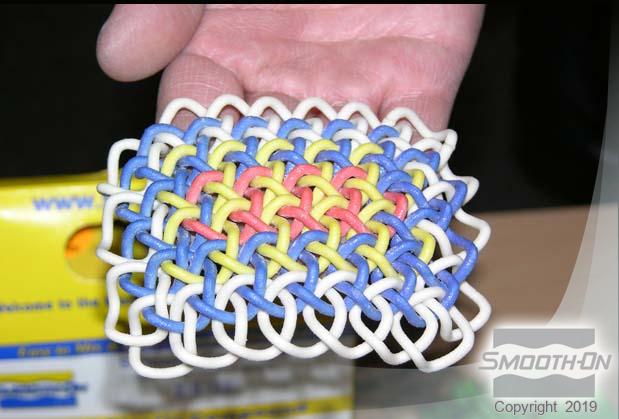

Rapid Technique LLC of England recently solved a daunting problem by using Smooth-Cast™ 326 liquid plastic as a coating for their 3D prototypes. Their technique designs and makes ingenius and complicated prototypes for toymakers, consumer product companies and technical design firms.

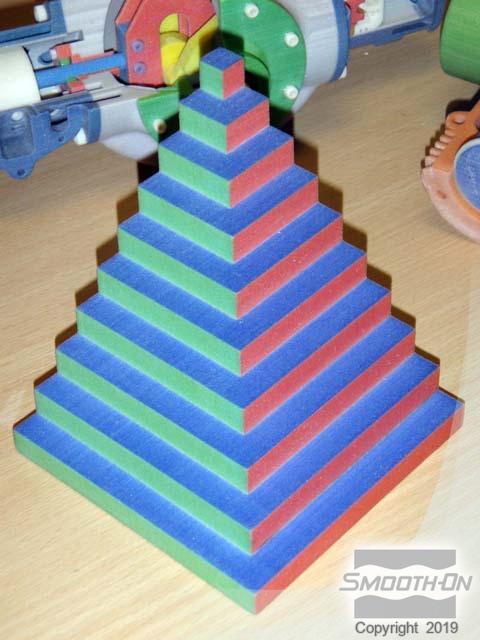

The 3D technology employed by their machine creates the 3D prototype by depositing layers of starch that are solidified by a liquid binder. The powder is distributed equally across the build platform in layers repeatedly until the 3-dimensional object is formed.

Forced air then blows excess powder off the piece.

Because the prototype models are made from starch, they are highly susceptible to humidity and other environmental forces. Rapid Technology discovered that SC-326™ could be combined with alcohol (to lower viscosity) and sprayed on the SC-326™ pieces. They mix Parts A & B with the alcohol in a spritzer bottle to spray it on the finished pieces.

The SC-326™ thoroughly and uniformly coats the models to make them impervious to the elements and therefore much longer lasting. The SC-326™ coatings also make the models more durable and impact resistant. The SC-326™ is mainly invisible, does not interfere with surface detail and gives an accurate representation of the model.