Are any Smooth-On urethane or epoxy resins “UV Stable”?

Stability in the presence of ultraviolet light or “UV Stability”, as it applies to resin products, is a fallacy. All resins will be affected by ultraviolet light over time and the best any resin manufacturer can offer are products that are “UV Resistant”. The effect of UV light on a resin casting will vary depending on the intensity of the UV source (such as the sun) and duration (amount of time the casting is exposed to the UV light source).

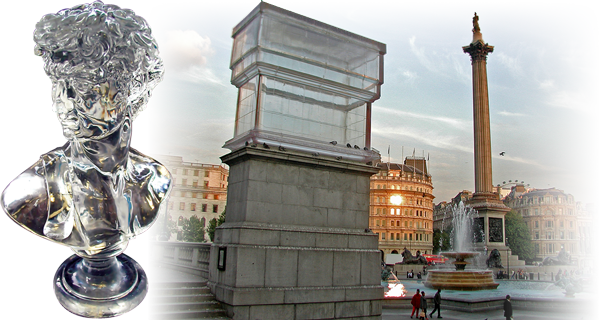

A simple comparison would be a resin casting displayed outdoors in a part of the world that does not get much sunlight, such as Dublin, Ireland, vs. the same casting displayed outdoors in a part of the world that gets a lot of sunshine and intense ultraviolet light, such as Las Vegas, Nevada (USA). A casting made from UV resistant resin, such as Smooth-On’s Crystal Clear resin, will remain minimally affected far longer in Dublin, Ireland.

The Smooth-On laboratory has a calibrated “UV chamber” that we use to measure the effects of UV and establish a base line resistance for its resins. We expose a small, flat sample of cured resin to ultraviolet light cycling at a specific intensity, duration, relative humidity, etc. Our Crystal Clear resin products contain UV resistant additives and, in this flat configuration, have been proven to resist the effects of UV light for the equivalent of a year without a substantive change in appearance.

What are the effects of UV light on castings made with Crystal Clear resins? Depending on variables such as casting configuration, UV intensity and exposure duration, etc., castings may darken over time in the presence of ultraviolet light. They resist yellowing.

Will castings displayed indoors be affected by UV light? Fluorescent light emits low levels of UV radiation and will affect castings over time, although the effect will be gradual. Depending on casting configuration, you may not notice the effects for a very long time or ever.

What guarantees does Smooth-On offer as it relates to resins not being affected by UV light? None. Smooth-On cannot be responsible for user aptitude and has no control over how its resin products are used or where castings are ultimately displayed. We have years of customers being successful in using our Crystal Clear Series of UV resistant resins for making clear castings for both indoor and outdoor applications. This applies to projects on a small scale (castings that are a few pounds or kgs.) or very large scale (castings that are thousands of pounds or kgs.).

Following directions carefully is always best practice and a small-scale test for any product is recommended to determine suitability for your application before investing in large quantities of material.