How to Make a 2 Piece Core Mold: Concrete Urn Example

Step 6: Making Vent Holes

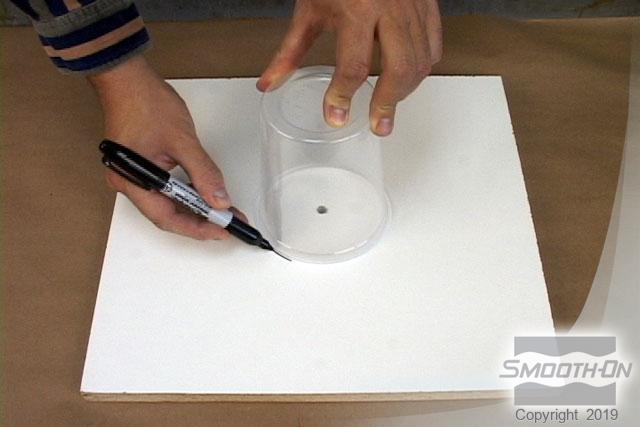

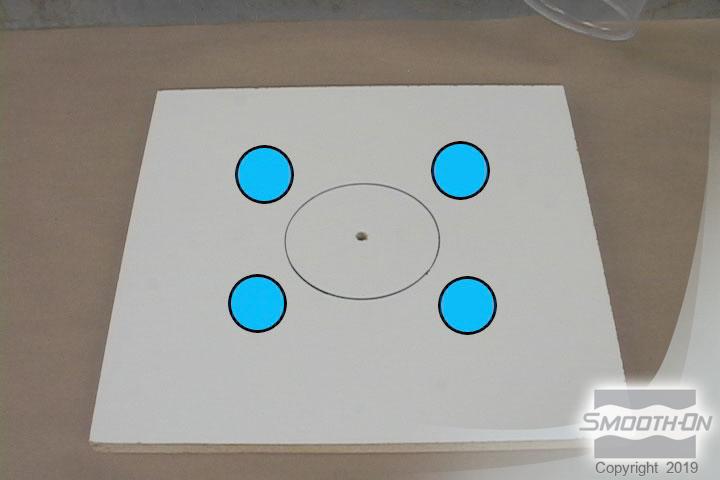

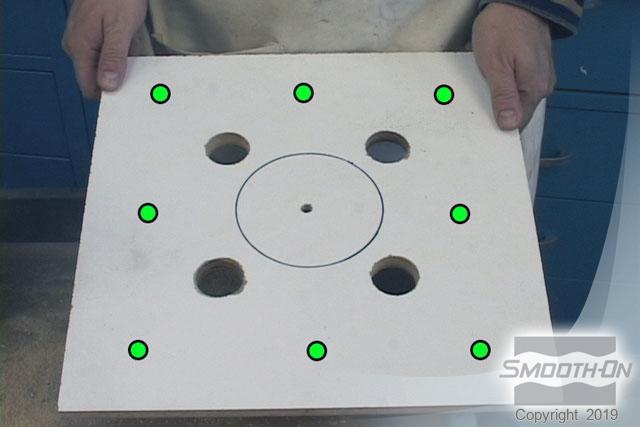

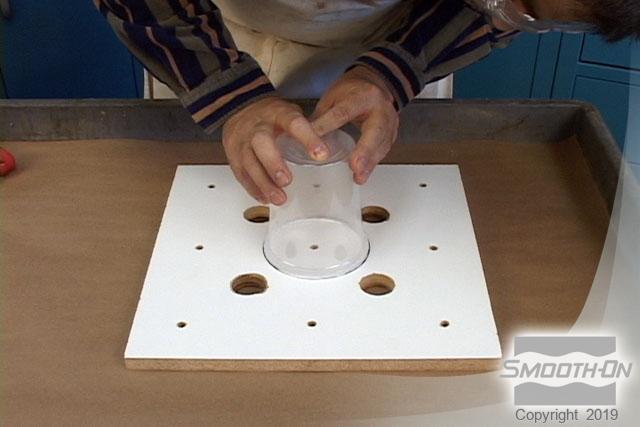

MAKING THE CORE SECTION: Place a plastic container on the center of the baseboard and mark the outline. Drill four 1'' (2.5 cm) holes. This is where the mold rubber will be poured to make the second half. 1/4'' (6mm) vent holes will be drilled in highlighted areas.

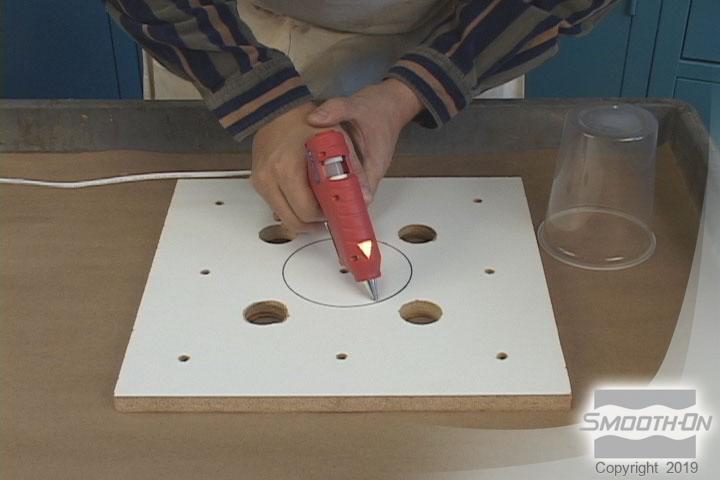

Vent holes will minimize air bubbles in the cured rubber. Hot melt glue is then used to adhere the plastic container to center of the board. Hold in place for ten seconds to ensure proper adhesion. Place the core section into the mold caviity. The alignment point is marked on the outside of the base and the mold box. Adhere the core section with drywall screws. Use modeling clay to seal the seams.