How To Make a 3‑D Aquarium Background Using Foam‑iT!® 5

Step 2: Applying Rebound™ 25

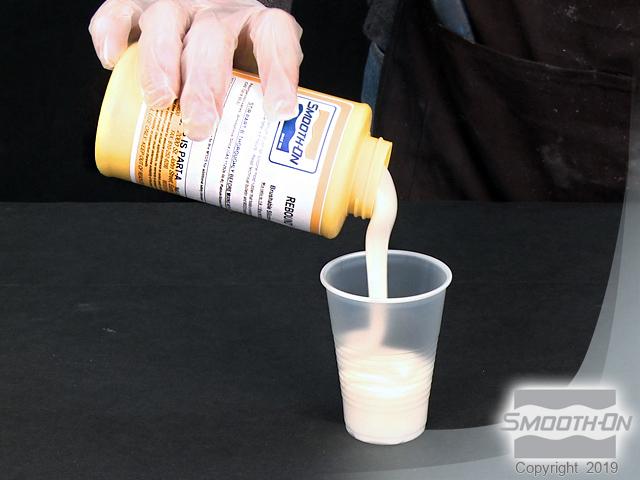

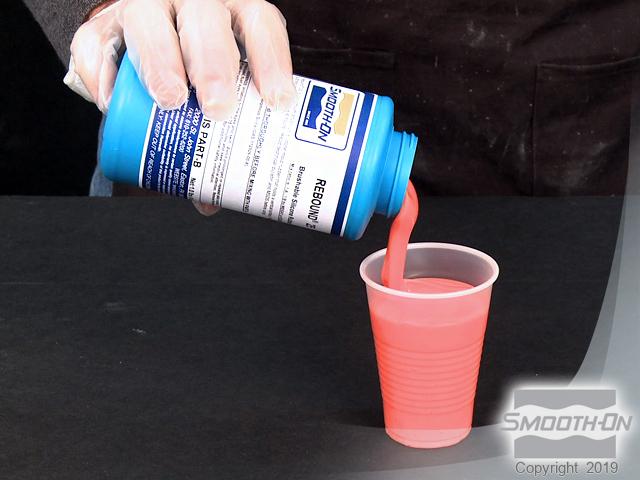

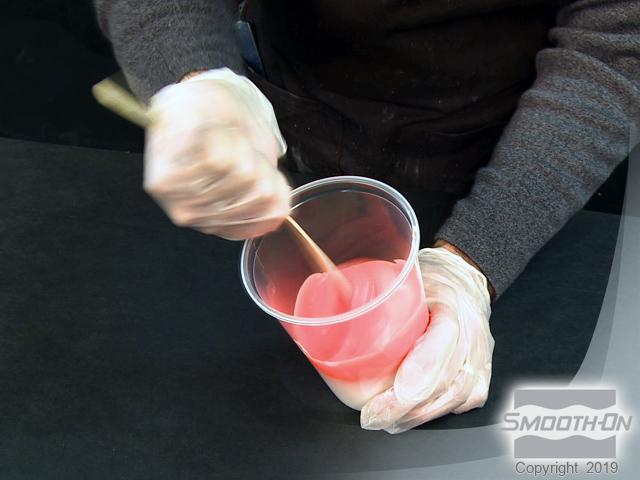

Rebound™ 25 brushable silicone rubber is used to make the mold. Dispense part A. Then, dispense an equal amount of part B. Mix parts A and B thoroughly until there are no color streaks.

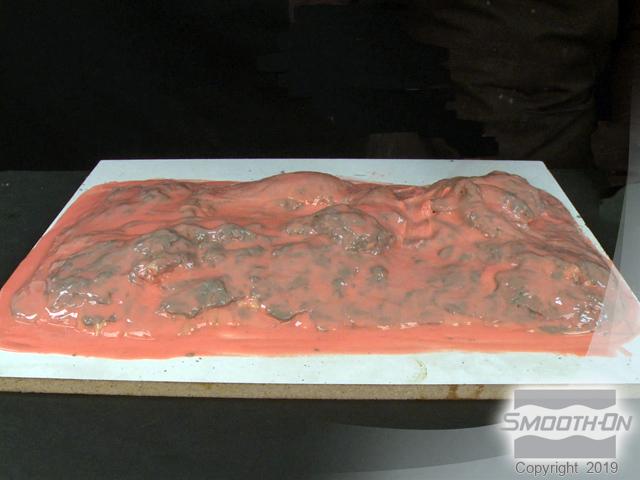

Apply an initial thin first layer. Use a stippling motion to force liquid rubber into deep detail. The first layer of mold rubber is allowed to partially cure. In order for subsequent layers to bond to previous layers, they must be added while the previous layer is partially cured, not fully cured (tacky but not in a liquid state). Keep adding more layers to build up to a thickness of 3/8''.

Once fully cured, trimming perimeter edges allows for better registration between the rigid support shell that will be created over it. It is now ready for the rigid support shell to be applied.