How To Use Alja‑Safe™ Alginate to Cast Silicone Body Parts

Overview

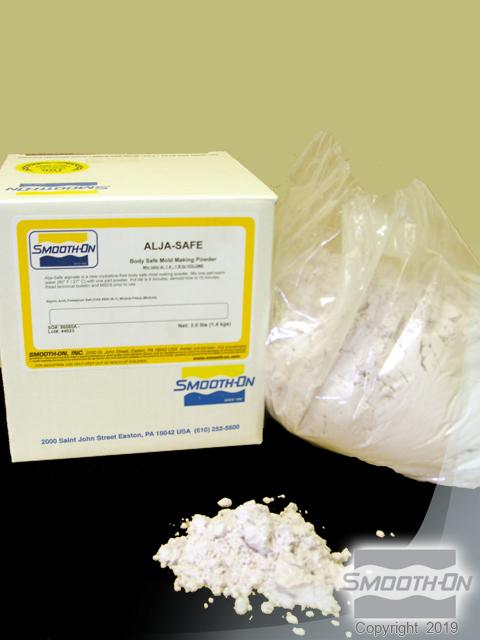

What’s Sets Alja-Safe™ Apart? In addition to being an exceptional body molding material, Alja-Safe™ alginate does not contain free crystalline silica (a known carcinogen). Not only does this make Alja-Safe™ safer to use, it also means that you can cast platinum silicone rubbers directly into finished molds. Platinum silicones can often bond in other alginates that contain crystalline silica.

Alja-Safe™ also captures detail better than other alginates, giving you a more accurate reproduction of your original. Alja-Safe™ is easy to use and cures quickly. It reproduces fine detail and makes an excellent temporary mold – good for one or two reproductions of any body part.

This sequence shows how to make a perfect reproduction of an entire arm.

Materials Used in this Tutorial

- Alja-Safe™

- Plastic Tube

- Sulfur Free Clay

- Melamine Board

- Hot Glue Gun

- Water

- Mixing Containers and Sticks

- Drill

- Squirrel Mixer

- Ecoflex™ 00-30

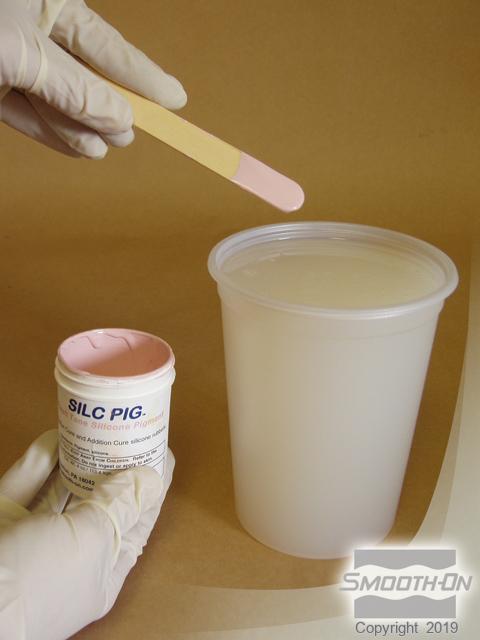

- Silc-Pig™ Fleshtone

- Vacuum Chamber

- Mixing Containers

- Mixing Sticks

Step 1: Preparing Materials

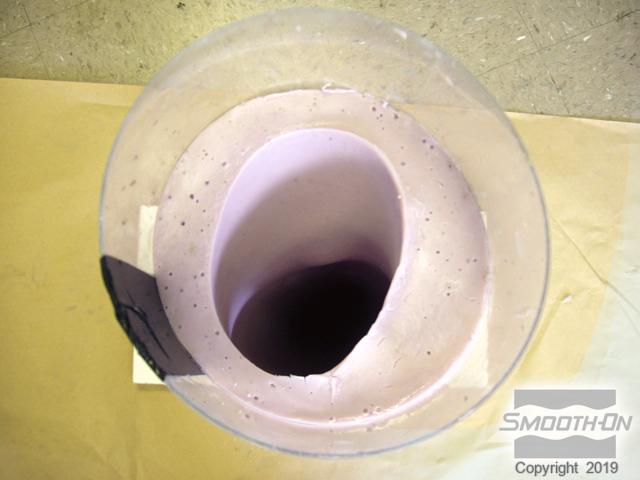

Begin by creating a containment field to hold the Alja-Safe™ molding gel. Tape a plastic tube along the seam line to ensure stability and adhere the plastic tube to a board using clay. Make sure the tube is completely secure - hot melt glue may also be used.

Alja-Safe™ molding gel is a powder that is mixed in equal parts with water. Measure out the appropriate amount of water. With water (80°F/ 27°C), Alja-Safe™ will have a working time of 8 minutes and a demold time of 10 minutes.

Step 2: Mixing and Applying Alja-Safe™

Begin by pouring water into the mixing bucket, and then adding Alja-Safe™ to the water. Use a drill powered turbine mixer to mix Alja-Safe™, as this will ensure a proper and thorough mixture. Now, place the model's arm inside the tube and pour more Alja-Safe™ around the model's arm. Be sure the model is not touching the side or bottom of the container or the finished mold will turn out deformed.

Hold that pose: Alja-Safe™ will set in about 10 minutes. Once Alja-Safe™ has set, it is time to remove the model's arm.

Step 3: Demolding Arm From Alja-Safe™ Mold

Slowly and careful wiggle the model's arm free from the alginate. Caution: removing the arm too quickly can cause tearing in the mold. Once the arm has been removed, the Alja-Safe™ mold is ready to be cast into.

Step 4: Preparing Ecoflex™ 00-10

Measure platinum silicone rubber, in this case, Ecoflex™ 00-30 to make a super soft silicone replica. Ecoflex™ is measured in equal parts by volume. To give the finished piece some realistic color, add Silc-Pig™ Fleshtone silicone pigment to Part B. Thoroughly mix the pigment into Part B prior to combining with Part A. Combine Parts A and B and mix thoroughly until there are no color striations present in the mixture.

For best results, Ecoflex™ 00-30 should be vacuum degassed prior to pouring into the mold. This will help eliminate any bubbles from causing defects in the finished piece. Once the rubber has been degassed, it can be poured directly into the Alja-Safe™ mold.

Step 5: Casting and Demolding Ecoflex™ 00-30

Pour the silicone to the top of the mold. Ecoflex™ 00-30 has a demold time of about 4 hours. Once the rubber has fully cured, the Alja-Safe™ mold can be removed. Alginate molds are typically one-time use as they must often be broken apart to removed the castings. Continue peeling away the Alja-Safe™ until the casting can be removed.

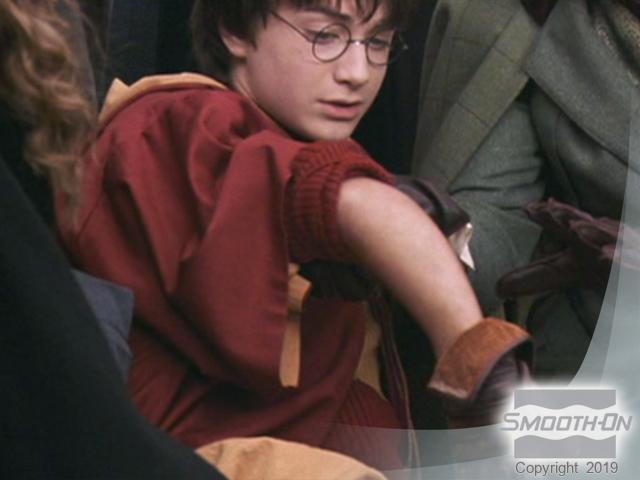

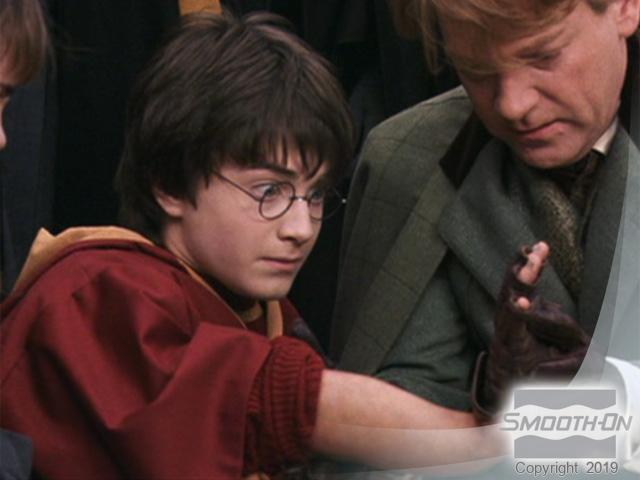

Step 6: Fake Arm

The Alja-Safe™ in combination with the silicone rubber has created a perfect reproduction of the model's arm. Detail as small as a fingerprint has been accurately captured. Ecoflex™ 00-30 is extremely soft and stretchy so it can be twisted, stretched, and manipulated in many ways without breaking or tearing.