How To Use Body Double™ FAST SET to Make a Mold of a Head

Overview

Body Double™ Silicone Rubber is used by both professionals and hobbyists to make ultra-high definition impressions directly off the human body. In their cured state, molds made using Body Double™ Silicone Rubber exhibit virtually no shrinkage. Furthermore, Body Double™ molds will maintain their dimensional stability for many years even after being cast many times. Body Double™ is skin safe and certified by an independent laboratory.

There are two versions of Body Double™ available - STANDARD SET & FAST SET. There are only three distinct differences between the two versions:

- Pot Life - the amount of time you have to work with the material to get Part's A & B mixed thoroughly and applied before it gels. The STANDARD SET has a 5 minute Pot Life; the FAST SET has a 90 second Pot Life.

- Cure Time - how long it takes for the silicone rubber to fully cure. The STANDARD SET has a 25 minute Cure Time; the FAST SET has a 6 minute Cure Time.

- Color - the STANDARD SET has a purple color when thoroughly mixed; the FAST SET has an Aqua Green color when thoroughly mixed. We gave them different colors so users will know which version they are working with.

It is possible to incorporate both versions of Body Double™ into one mold, especially in situations where a longer Pot Life in the silicone rubber is desired in order to pick-up ultra-high definition on the surface of the skin, such as facial features. In the sequence below, both versions of the silicone are used in the mold of the model's head.

This photo sequence details creating a fast, one-piece, cut seam mold of an entire head using Body Double™ FAST SET lifecasting silicone.

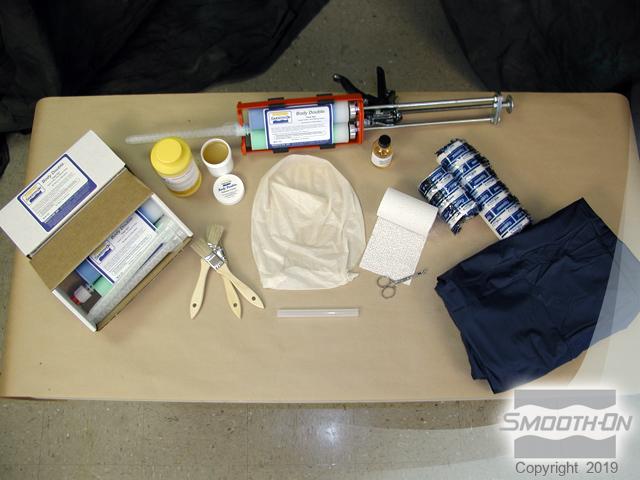

Materials Used in this Tutorial

- Bald Cap

- Body Double Fast Set

- Paint Brushes

- Gypsum Bandages

- Dispensing gun

- Earplugs

- Straw

- Mixing Sticks

- Mixing Containers

- Smooth-Cast 300

- Release Cream

- Scissors

- Ear Plugs

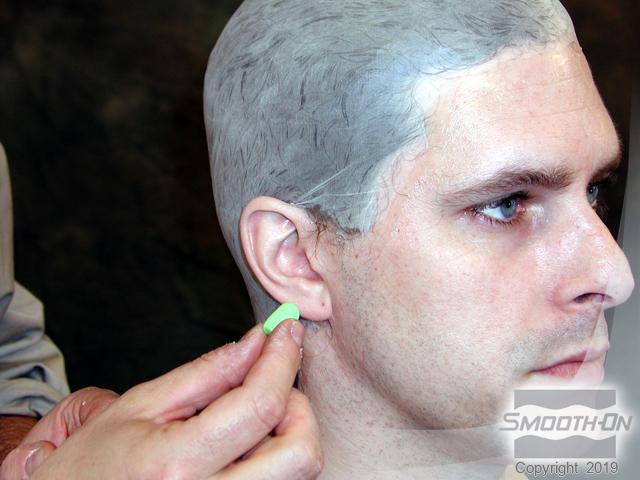

Step 1: Preparing Materials and Model

Begin by assembling and preparing supplies, while earplugs are placed inside the ear cavity to prevent Body Double® from running into the ear. Body Double® silicone will not stick to human skin, however, it will encapsulate hair. Body Double Release Cream was developed to release the rubber from all surfaces including hair-covered human skin, so apply a layer of Body Double Release Cream. Secure the Body Double® FAST SET cartridge into the dispensing gun. Using the dispensing gun allows the mold maker to quickly mix and apply more material.

Step 2: Applying Body Double Fast Set Silicone

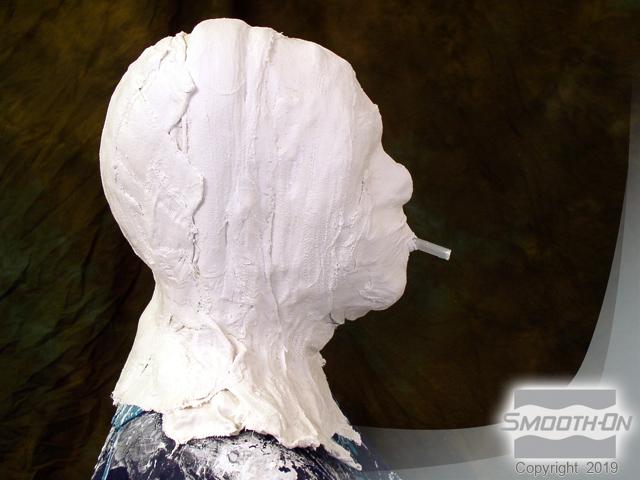

Dispense Body Double® FAST SET into a cup and carefully brush it onto all areas of the model's face and head. It is important that the first coat achieve thorough coverage over all parts of the head. As more material is needed, Body Double® FAST SET can be meter mixed directly from the dispensing gun. This saves time when working with fast setting materials. Continue to build up more Body Double® FAST SET in layers over the model's head until ultimate mold thickness is approximately 3/8'' (1 cm). Once the silicone has been layered to an appropriate thickness, a rigid support shell must be built. Before creating the shell, allow the Body Double® to fully cure (approximately 5 minutes after application).

Step 3: Applying Support Shell

The support shell is built in two pieces with medical grade plaster bandages. Only use medical bandages - other grades will generate too much heat to use safely on a live model. When one half of the support shell has been built, begin on the second.

Mold maker's tip: Brushing a thin coat of petroleum jelly over the Body Double® prior to applying bandages will minimize chances of suction or mechanical locking of support shell.

Use more plaster bandages to add further stability to the support shell. Allow bandages to cure for approximately 15 minutes.

Step 4: Demolding

Once the plaster bandages have cured, the support shell can be removed. To remove the Body Double® mold, begin by carefully cutting the mold up the back up the head. Once cut, slowly peel the mold away from the model's head.

Below you can see the view inside the open cavity of a Body Double® silicone mold.

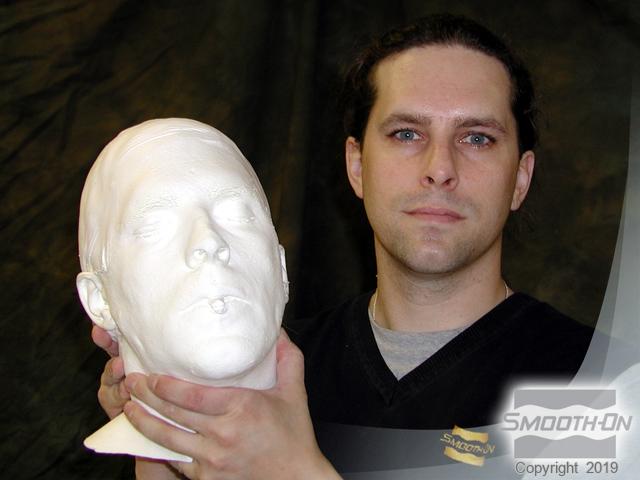

Step 5: Preparing Mold For Casting / Casting

The mold is seated in the support shell and is ready to be cast into. Mix Smooth-Cast® 300 resin and carefully pour into the mold. Once the resin has cured (about 10 minutes), remove the Body Double® mold from the casting.

The finished casting reflects perfect detail captured from the model. Body Double® lifecasting silicone will pick up detail down to a fingerprint. A Body Double® mold can be used many times to create multiple reproductions. The possibilities are endless! Body Double® lifecasting silicone can be used to create many kinds of lifelike reproductions. Castings can even be sanded and painted to look like real skin!