How To Make a Brush On Mold of an Antique Rifle

Step 5: Applying and Demolding Support Shell

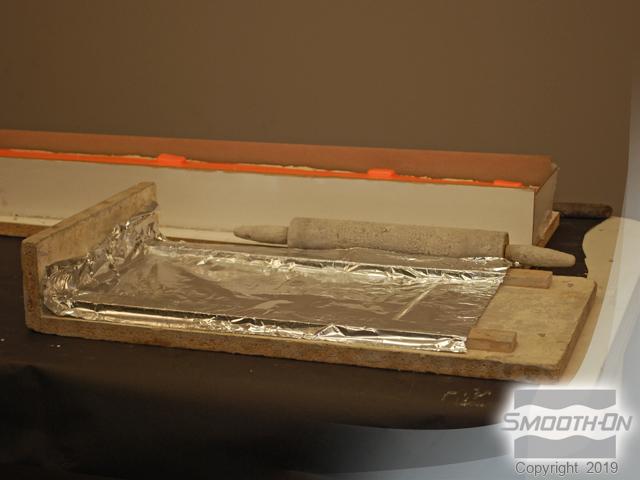

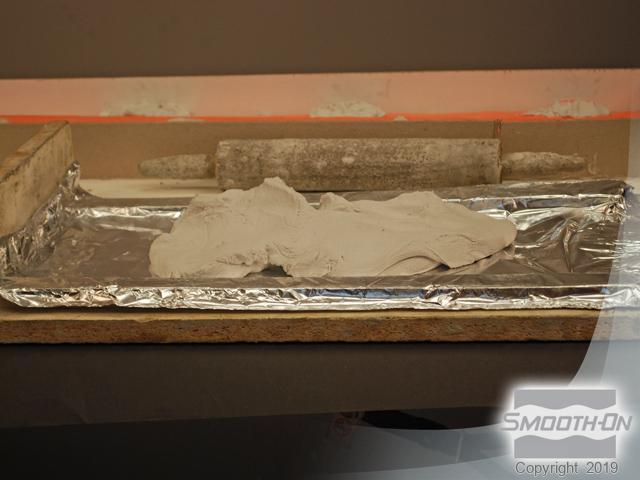

Free Form® Air will be used for the support shell, chosen for its light weight and durability. Equal parts of Free Form® Air are measured out by volume and mixed by hand. A rolling pin and Clay Board covered in aluminum foil will be used to roll out even thicknesses of the Free Form® Air which is then spread across the board.

Another layer of Aluminum foil is placed over the Free Form® Air then smoothed with the rolling pin. The Aluminum foil peels easily away, revealing a nice, even layer of Free Form® Air. The Free Form® Air is placed over top the Rebound® and the bottom piece of Aluminum foil is pulled away from the putty. The method is repeated until the whole mold is covered in a uniform layer of Free Form® Air.

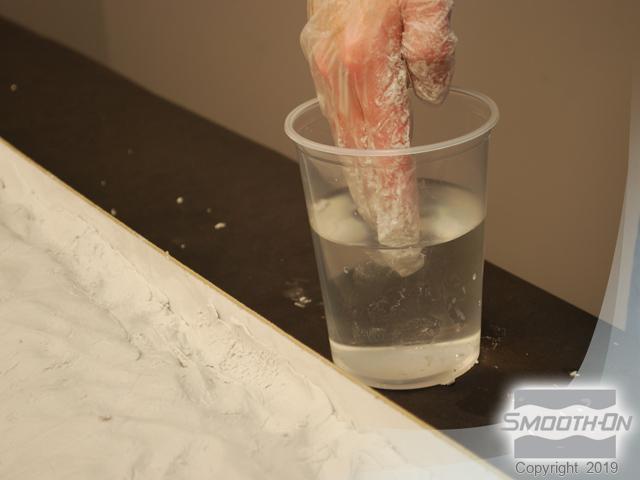

A gloved hand dipped in water will be used to smooth down the Free Form® Air to make a smooth, clean support shell. Water helps even out the putty, producing a finished look. Once allowed to cure overnight, the cardboard walls are removed and the model is lifted from the board in order to start the second half of the support shell.