How To Mold and Cast a Resin Sculpture ‑ Ghost Rider

Step 3: Applying Rebound™ 25

Once the Free Form™ AIR epoxy is cured, Mann's Ease Release™ 200 is applied to the piece and allowed to dry.

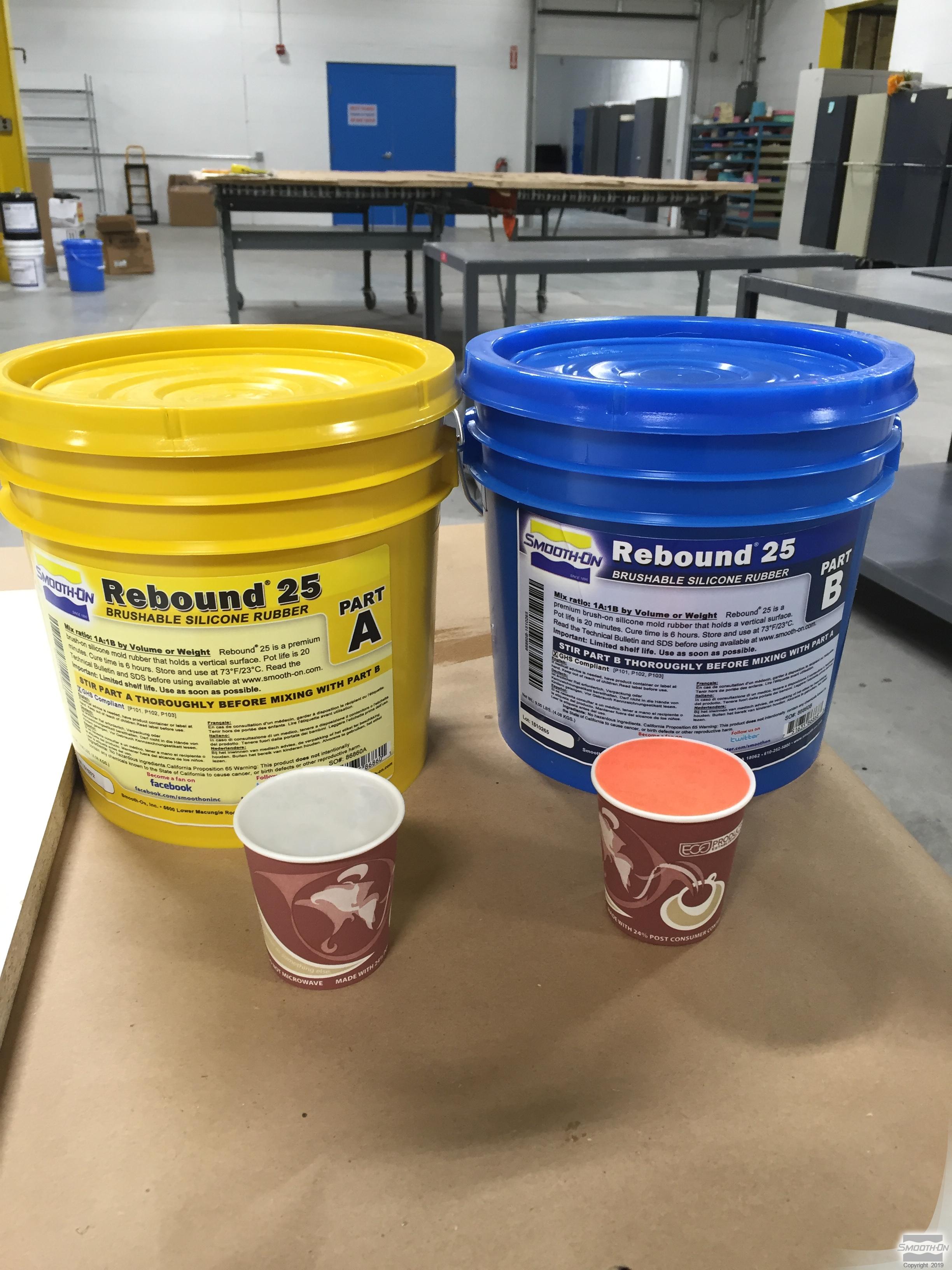

Rebound™ 25 silicone rubber is measured 1A:1B and dispensed into a mixing container. The Rebound™ 25 is mixed for 3 minutes, while scraping the sides and bottom of container many times to eliminate all color streaks.

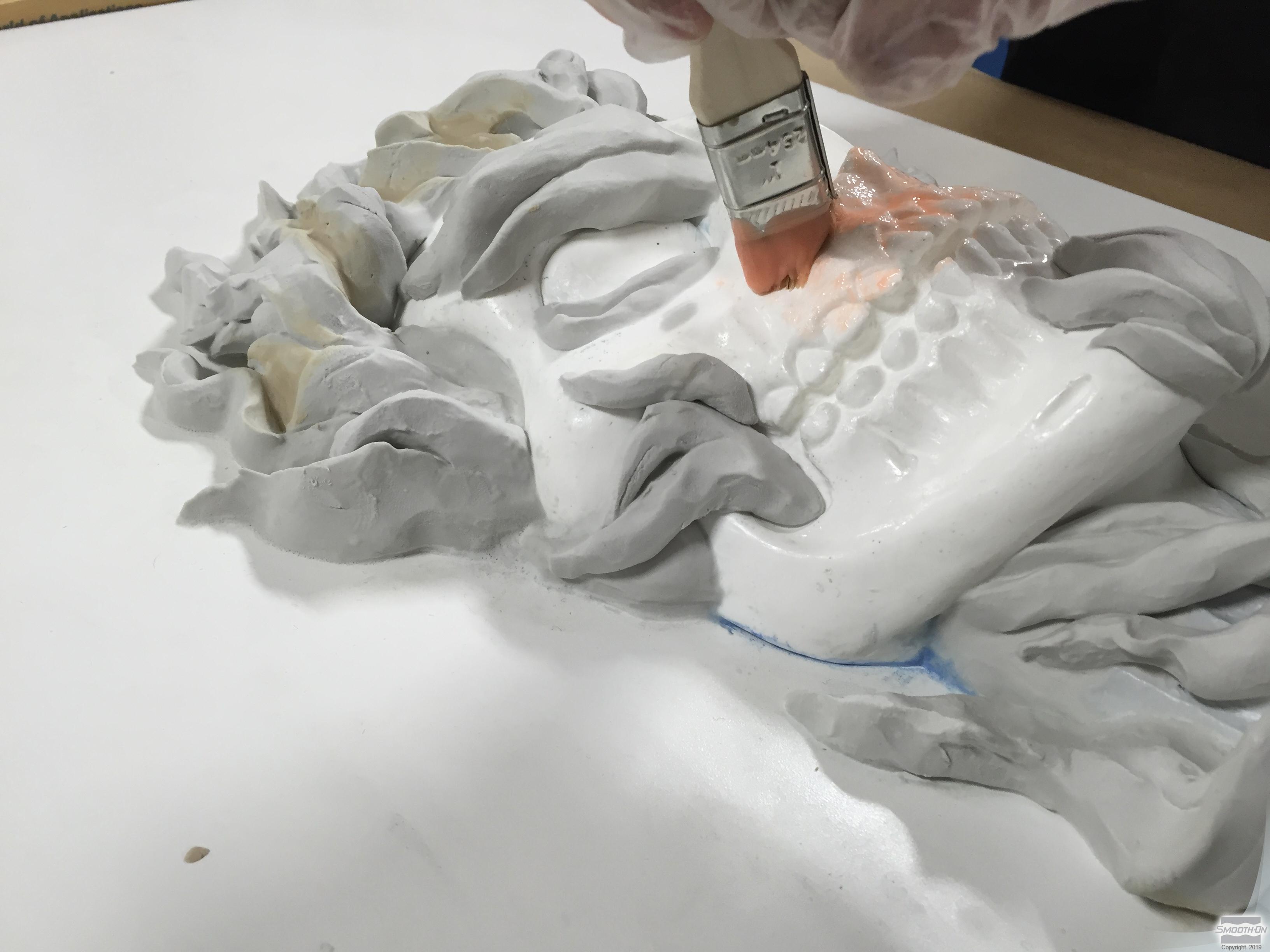

A very thin layer of Rebound™ 25 silice is stippled onto the model. Rubber is worked into fine detail, covering the entire model and creating a 3 inch (7.62 cm) flange in all directions around model. Allow rubber to cure 60 minutes until tacky. Rubber should be sticky to the touch, but does not come off onto a vinyl glove.

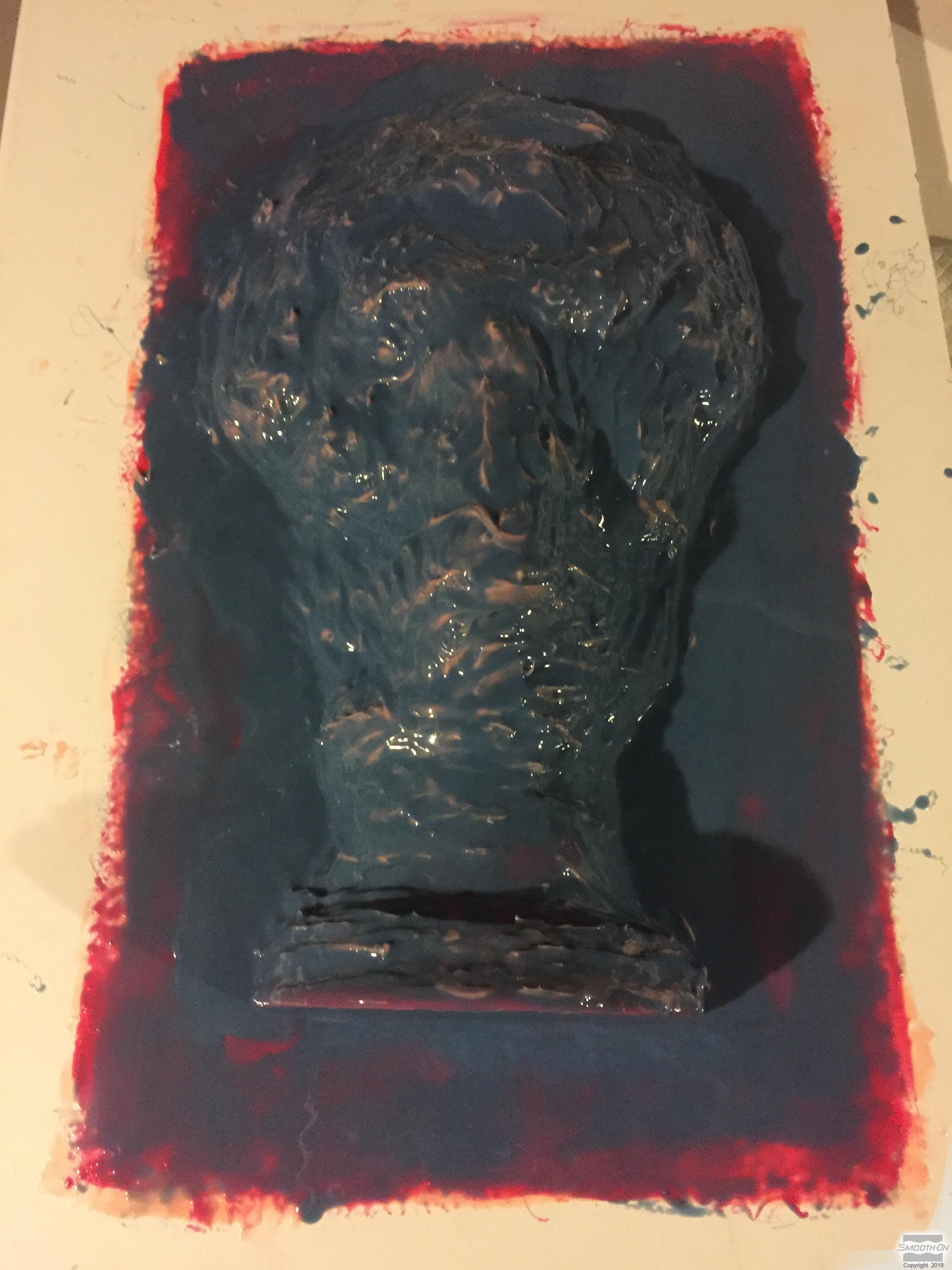

After the first layer is tacky, the second layer of Rebound™ 25 is mixed and applied. After the model and board are covered, let rubber cure for 60 minutes until tacky.

A third layer of rubber is thickened by measuring and mixing a small amount of Rebound™ 25 and adding 4 drops of Thi-Vex thickener to every 1 oz. of mixed Rebound™ 25. The thickened rubber will be used to fill any undercuts.

Next, another small batch of rubber is mixed and applied. Again, the rubber is allowed to cure for 60 minutes until tacky

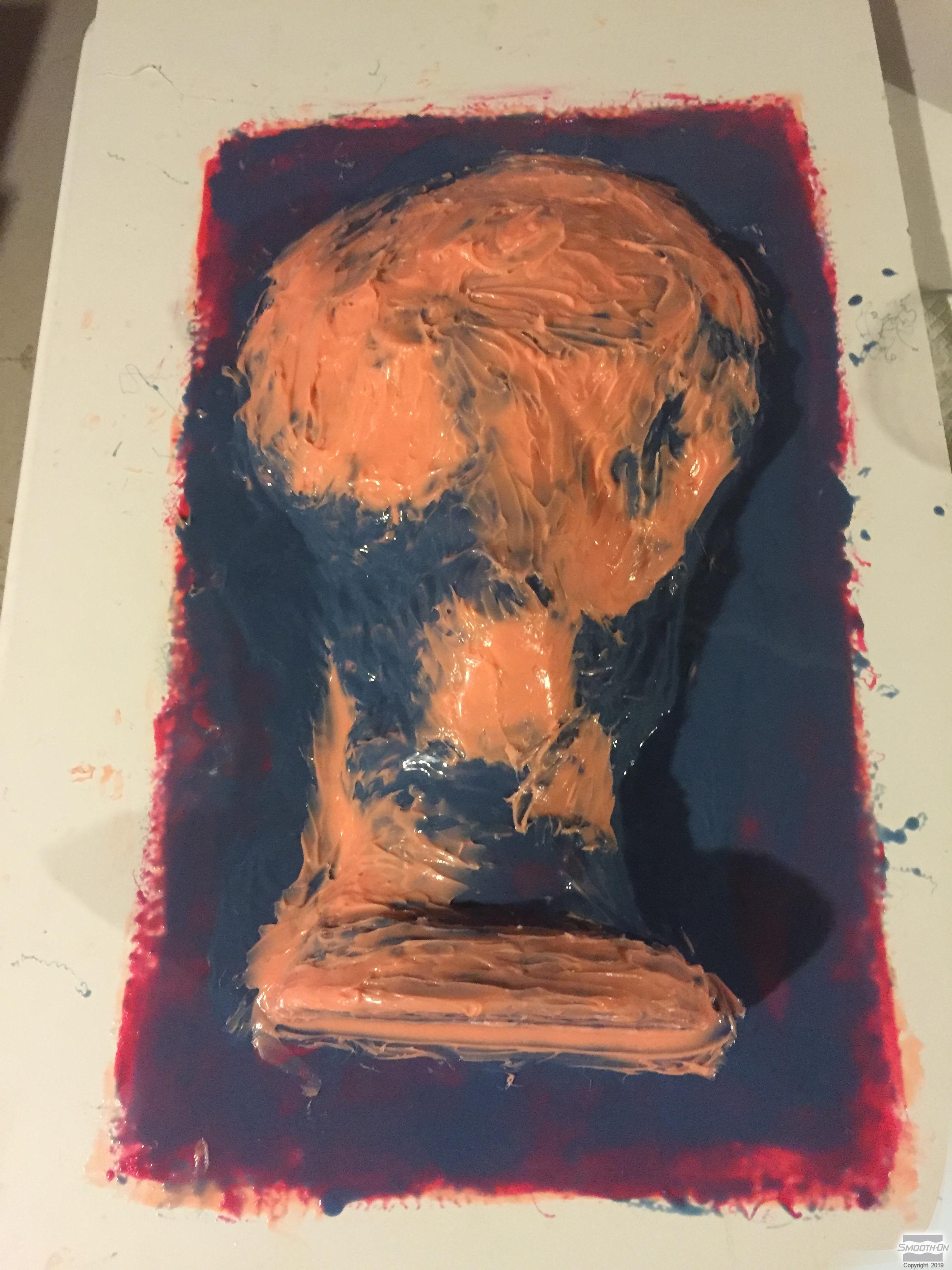

An additional small batch of thickened rubber is applied to further fill in undercuts and reduce sharp angles.

A final layer of Rebound™ 25 is applied and the rubber is allowed to cure for at least 6 hours at room temperature (73˚F/2\3˚C) before applying the Free Form™ AIR support shell.