How To Use Equinox™ Putty to Replicate a Sea Fan

Step 2: Creating a Mold Using Equinox™ 40 Silicone Putty

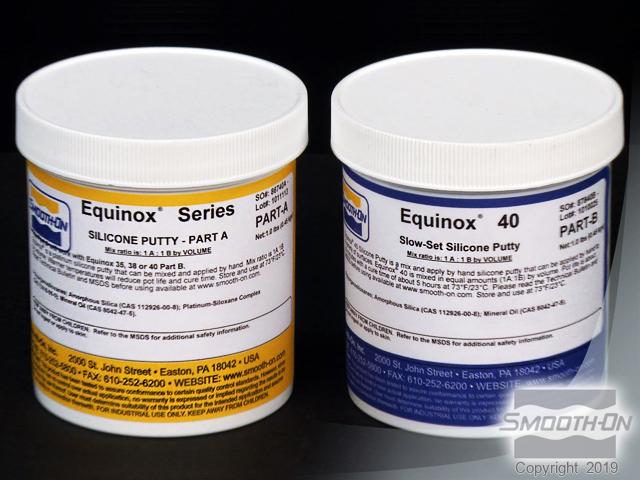

Equinox™ 40 silicone mold putty is used to create the mold. It has a mix ratio of 1 part A to 1 part B by volume. Two separate medium-sized batches of equal volume will be combined together and spread out as one sheet over the base boards.

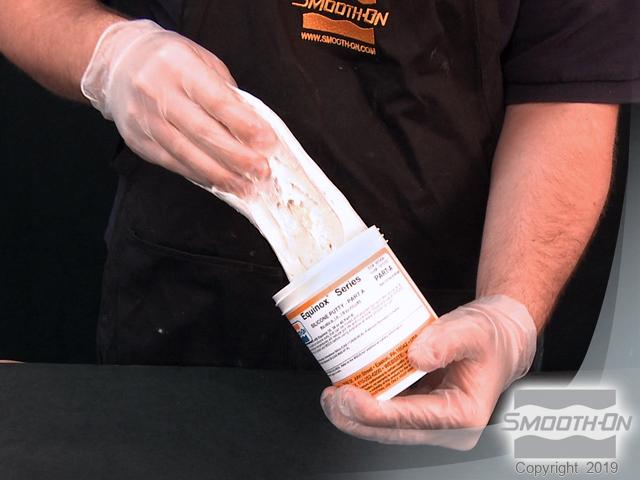

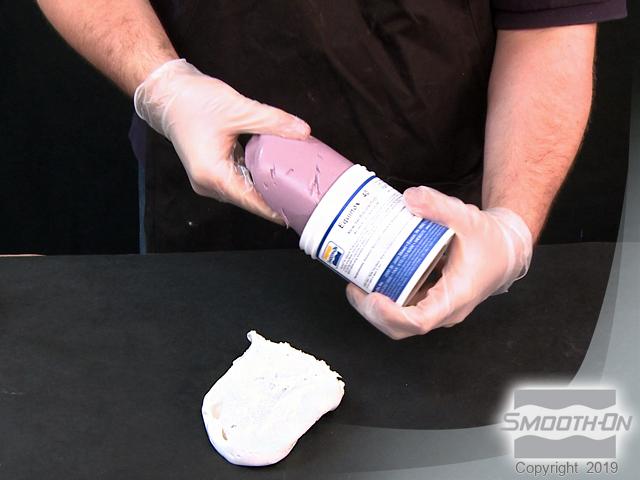

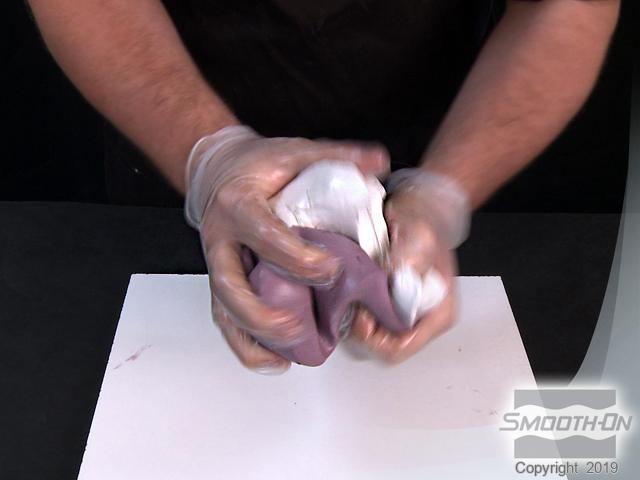

Now, dispense part A then dispense equal parts B. Mix part A and part B together. Equinox™ 40 has a pot life of 30 minutes. Continue mixing until there are no color streaks. Once the first batch is completely mixed, place it in a clean container on the side.

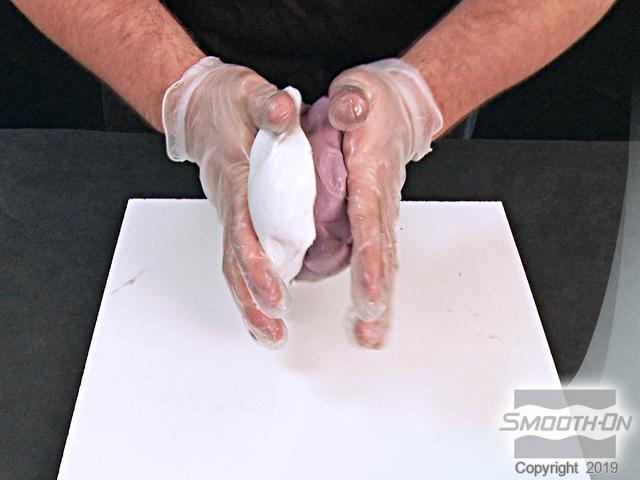

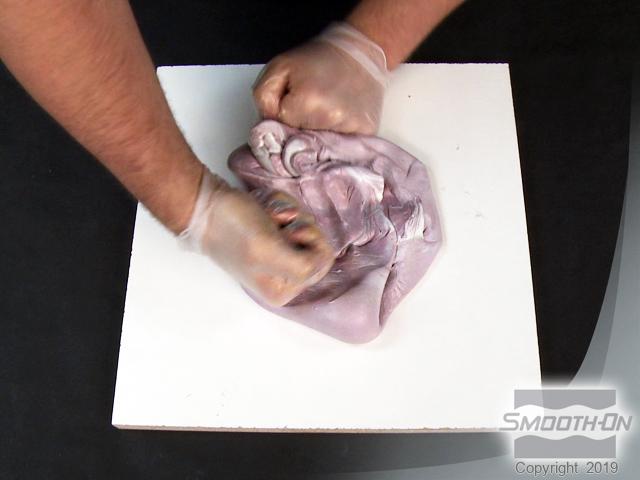

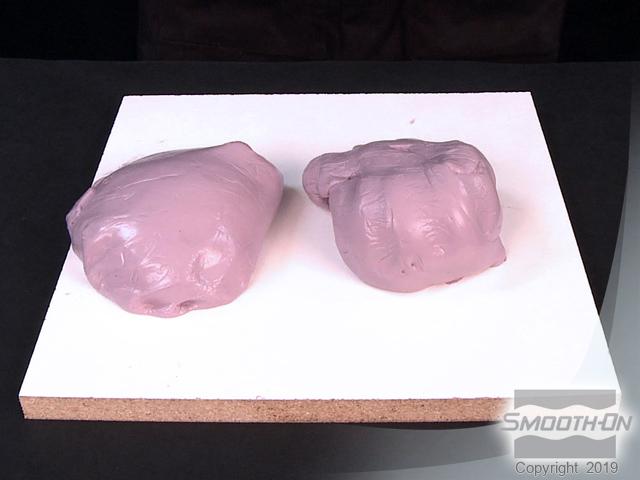

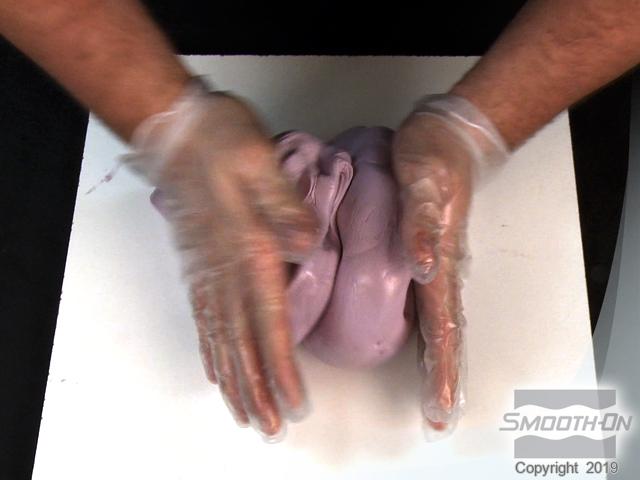

Then mix a second identical batch. Place the 2 batches of putty that were mixed separately together on your base board. Both batches of putty are ready to be combined. Combine both batches of putty into one larger portion. Knead the putty on the base board until both batches are blended together.

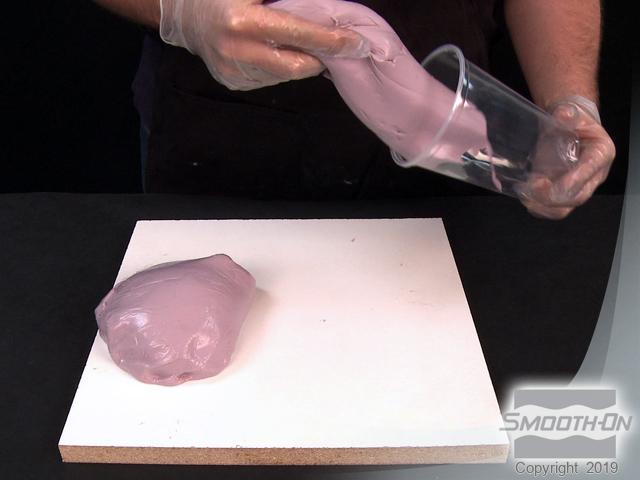

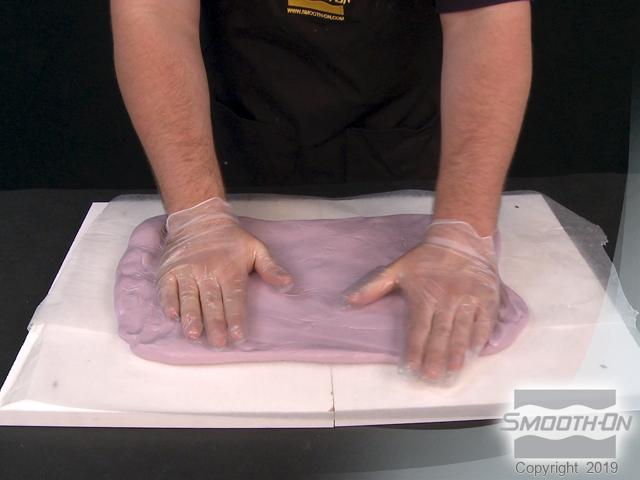

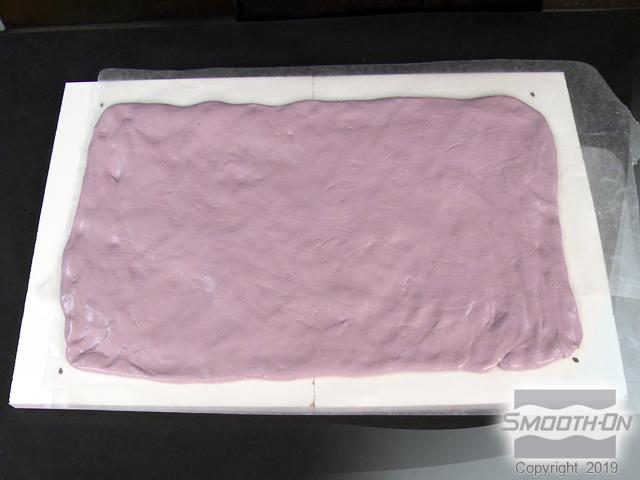

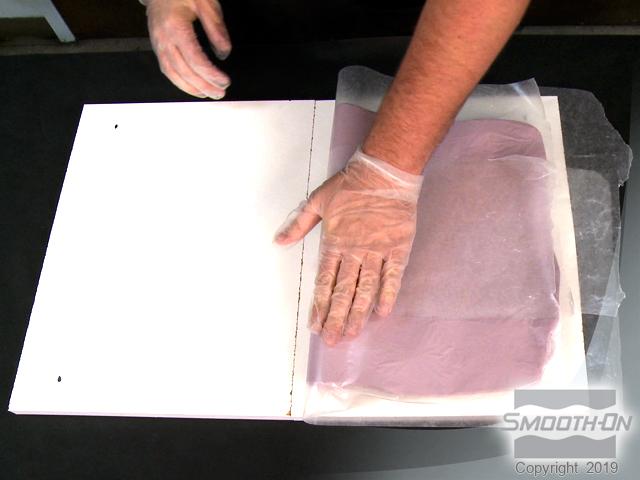

Starting from the center, apply downward pressure and spread the putty out towards the outer edges of the board using the perimeter dots previously drawn as a guide. The goal is to make the silicone putty sheet a uniform thickness of approximately 0.5'' (1 cm). Mold putty is spread out evenly onto wax paper-covered board.

Spray Ease Release 200 release agent on the entire surface of the mold rubber to prevent it from sticking to itself. Position your original sea fan on the right half of the mold putty. Press down gently but firmly so the fan is halfway embedded into the mold rubber.

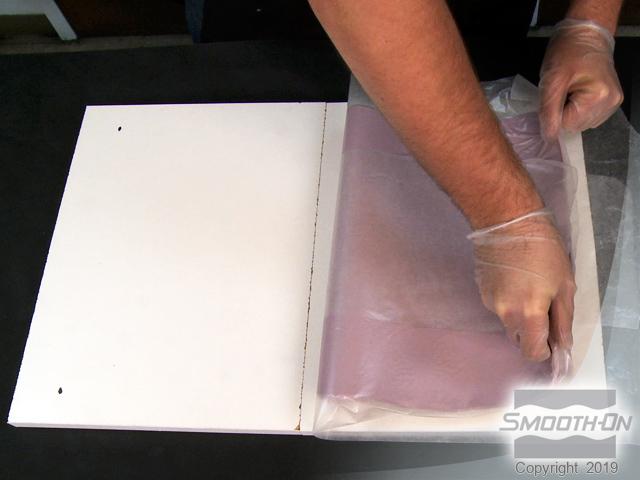

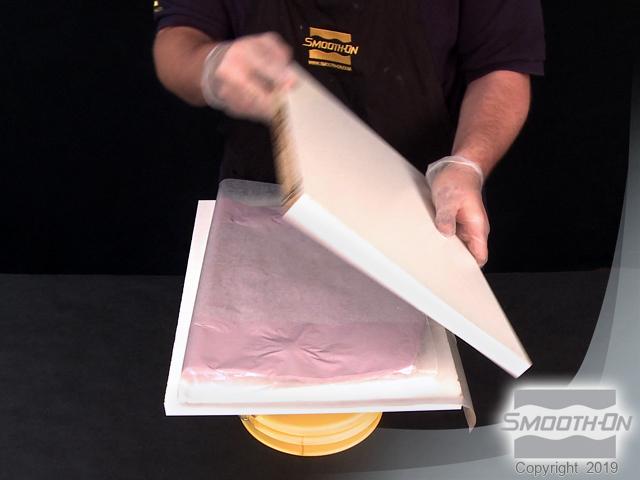

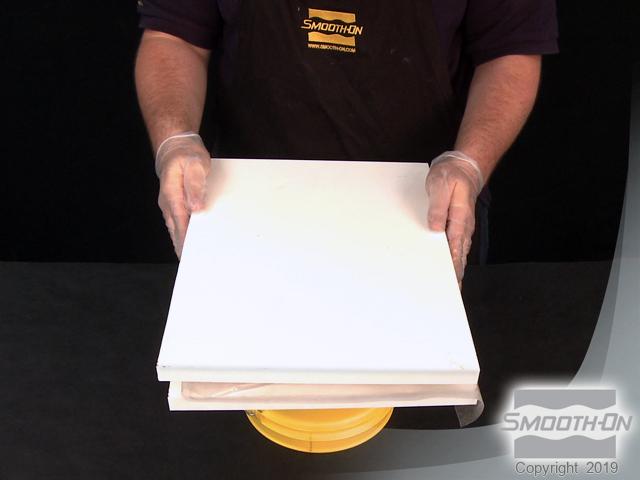

Fold the mold rubber as perfectly in half as you can, using the wax paper to assist you. Your goal is to gently encapsulate the sea fan model between the folded sheet of mold rubber. Even out the center seam by pressing gently. Do not disturb the original inside. Leave the folded rubber mold on half the base board and elevate it high enough to be clamped at each corner.

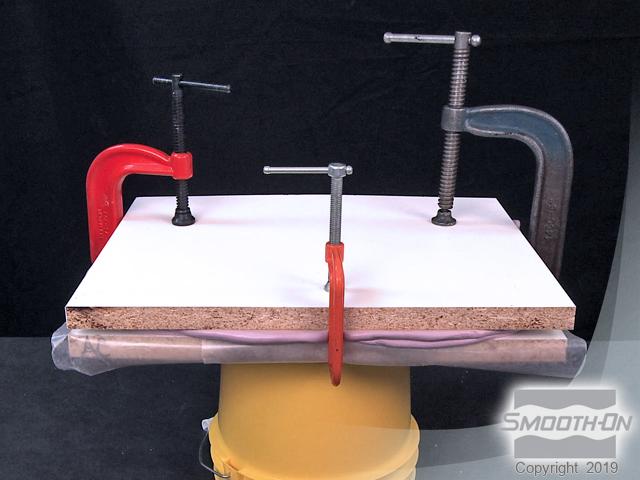

Using C-clamps, position a clamp at three equidistant points on the sandwiched boards, but do not tighten at this point. Tighten each clamp equally until uniform pressure is attained over the entire surface. Let Equinox 40 mold rubber cure for at least 5 hours.