How To Make a Face Casting with Alja‑Safe® Crystalline Silica‑Free Alginate

Overview

Alja-Safe® Crystalline Silica-Free Alginate is suitable for making temporary molds of the face, hands and other body parts.

What Sets Alja-Safe® Apart?

In addition to being specifically designed for making body molds, Alja-Safe® alginate does not contain free crystalline silica, a known carcinogen. Alja-Safe® is easy to use and cures quickly. It reproduces fine detail and makes excellent temporary molds.

You can then cast plaster, duoMatrix® NEO (polymer modified gypsum), or Smooth-Cast® 300Q ultra-fast urethane resin into the mold to make a reproduction.

Materials Used in this Tutorial

- Alja-Safe alginate

- Gypsum Bandages

- duoMatrix-G

- Water-Based Hair Gel

- Mixing Containers

- Turbine Mixer

- Salt

- Water

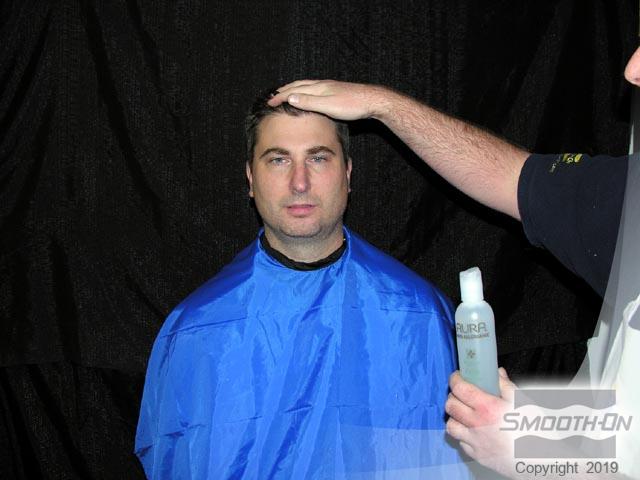

Step 1: Preparing Model and Materials

The models hair and eyebrows are prepared using water-based hair gel. The model is now ready to be molded. The Alja-Safe® alginate and water are measured out; slightly less water than alginate will make Alja-Safe® thicker in consistency.

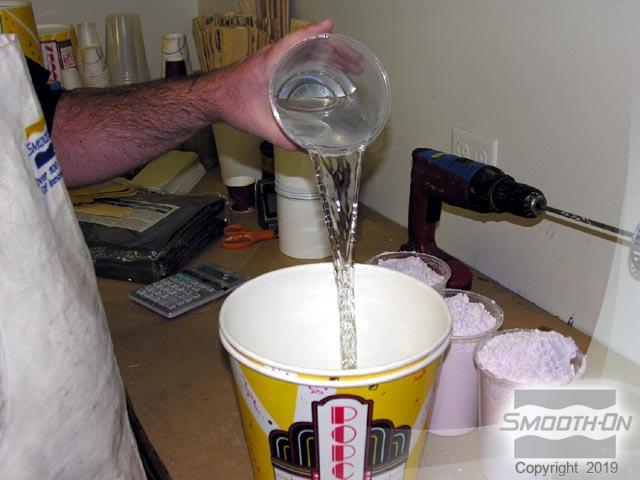

Step 2: Mixing and Applying Alja-Safe™

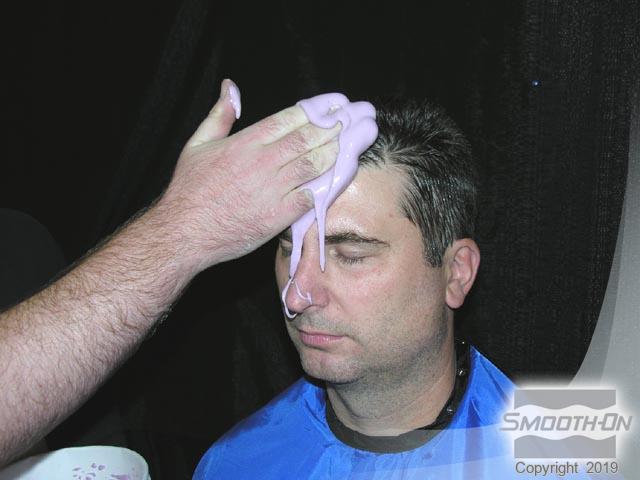

Next, water is added into the mixing container first. Then the Alja-Safe™ alginate is added into the water. For best results, the componenets are mixed while adding the power into the water. Using a Squirrel mixer attached to a power drill helps to blend a large batch of alginate consistently and fast.

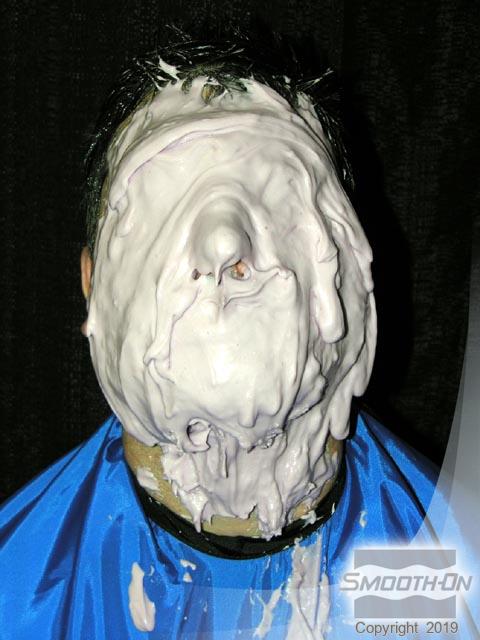

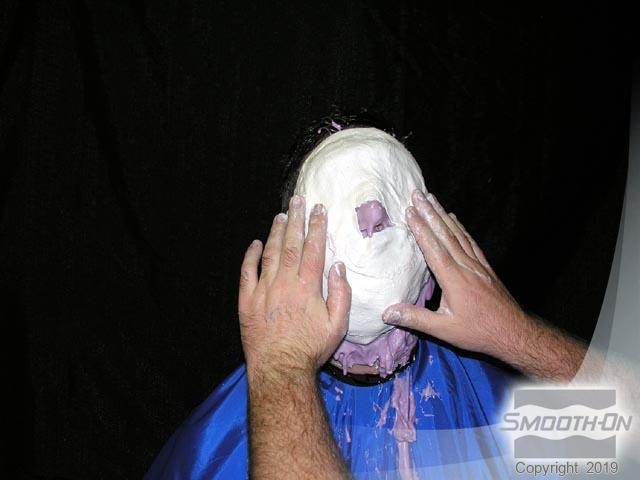

When the Alja-Safe™ alginate is thoroughly mixed, it can be applied to the model. The Alginate is applied from the top down. Alja-Safe™ will remain workable for about 8 minutes giving you time to work into all detail areas. More alginate is added until mold sufficiently thick (at least 1/2''/ 1.27cm). When the face is covered with Alja-Safe® alginate no more alginate is needed.

Note the holes in the nose - so the model can breath.

Step 3: Applying Gypsum Bandages for a Support Shell

Salt is then added into warm tap water (80°F/ 27°C) to accelerate dry time of plaster bandage. Plaster bandages are dipped in water to activate. Excess water is squeezed out of the plaster bandages and then applied directly onto the alginate.

The edge of the support shell is created first around the perimeter of the alginate mold. Plaster bandages will 'meld' into itself. The entire alginate surface area needs to be covered by the plaster bandages to ensure proper support.

The exterior of the plaster support shell is smoothed out while the bandages are still moist. A small piece of plaster bandage is used to create nose support. The plaster bandage support shell is now completed.

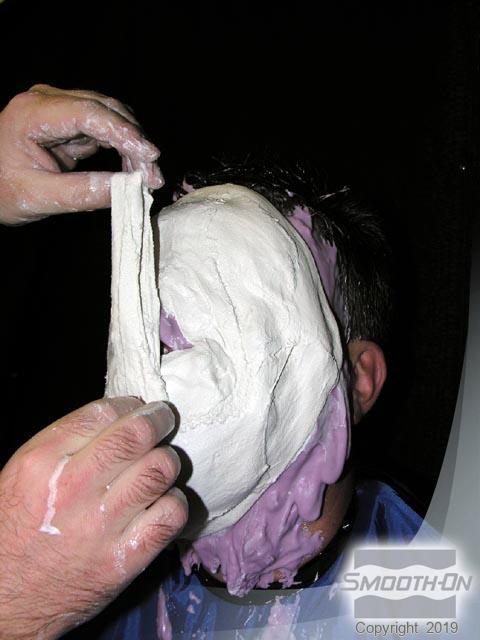

Step 4: Demold and Prepare for Casting

The demolding process begins with the mold leaning forward. Running a finger on the inside perimeter of the alginate mold will help to loosen it from the face.The alginate will separate from the face very easily. The alginate is supported by the plaster shell to prevent any tears from occuring.

Before the mold can be cast, the breathing holes in the nose must be sealed off. A small amount of Alja-Safe® is mixed up and applied. Attention is paid to filling in the nose holes without creating any new detail in the mold. A tongue depressor stick is used to smooth out the alginate, leaving the finished Alja-Safe® alginate mold with plaster bandage support shell.

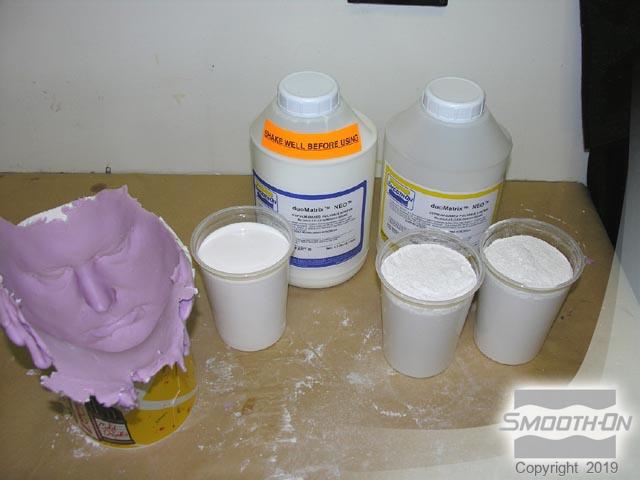

Step 5: Casting Final Piece with duoMatrix-G

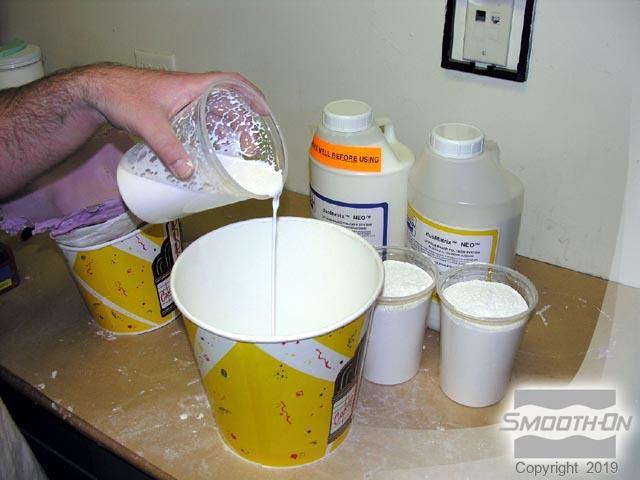

duoMatrix® NEO polymer-modified gypsum measured 2 Parts A : 1 Part B by Volume will be used to make a casting from the mold. The duoMatrix® NEO liquid is poured into the mixing container first, followed by the powder. A Squirrel Mixer attached to a power drill is used to mix the batch of duoMatrix® NEO thoroughly and fast. The duoMatrix® NEO is cast into the mold after being thoroughly mixed.

After 60 minutes, the duoMatrix® NEO casting is ready to be demolded. The first step in this demolding is to remove the support shell first. The Alja-Safe® alginate mold is then carefully removed from the casting, leaving the model with an exact replica casting of his face.