Making A One Piece Cut Block Mold

Step 5: Demolding

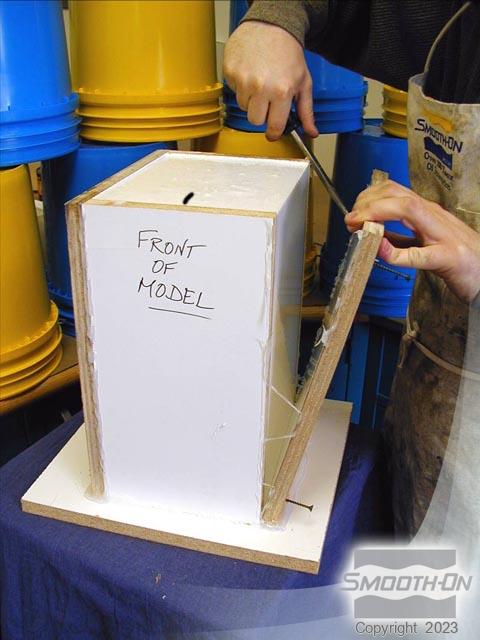

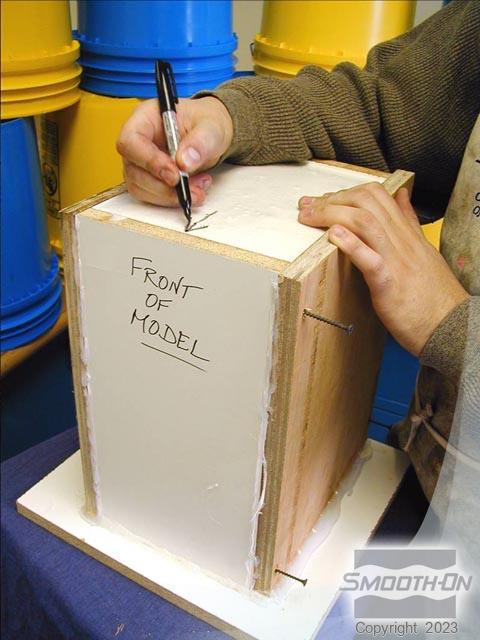

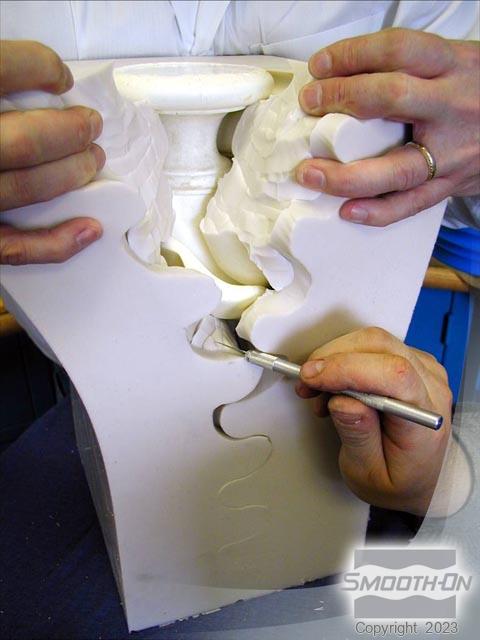

We do not want a seam on the face of our model. After the rubber cures another mark is made on the rubber itself indicating the front of the model, so that the seam in the rubber is not done on this side. The mold box is unscrewed, and isopropyl alcohol is used to soften and remove the hot glue sealing the box. The sides and base of the box are removed. The mold is turned upside down and, using a razor knife, a cut is made down one side of the model starting at the base of the model. Two people can make this task easier, with one person pulling the seam apart and the other doing the cutting. The cut is made in a zig-zag pattern, so as not to leave a straight seam. This will both hide the seam better when casting and allow the seam to be closed completely, the two sides of the cut locking together like the pieces of a jigsaw puzzle. The cut is extended until the original can be extracted from the mold.