Making A One Piece Cut Block Mold

Step 3: Vacuum De‑Gassing

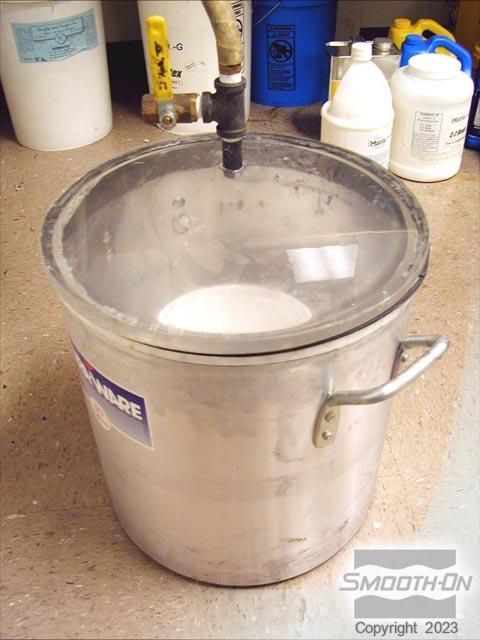

We chose to vacuum de-gas the material before pouring to eliminate any bubbles in the final mold. The mixed material is placed into the vacuum chamber after assuring that there is enough space above the liquid in the container for the material to rise and fall as any air bubbles burst. The chamber is attached to a vacuum pump and the chamber is drawn down to 29 inches of mercury. The material is allowed to foam and rise up. After the material falls again and the bubbles are largely gone, the vacuum pressure is released, and the material removed from the chamber. It is now ready to pour.