How To Make a 2 Part Trigger Guard Mold

Overview

A two-part mold is made of a flintlock pistol trigger guard using SORTA-Clear® 37 Silicone for the lost-wax process. Visibility is important in this application in order to view the hot wax when it’s injected into the mold. Perfect multiple wax reproductions are created, then used in the investment casting process.

Materials Used in this Tutorial

- SORTA-Clear® 37

- Ease Release 205

- Vacuum Chamber

- Wax

- Sulfur-Free Clay

- Wooden dowels

- Sprew/pour

- Foam board

- Hot Glue Gun

- Mixing sticks

- Mixing cups

- Exacto knife

- Paint Brush

Step 1: Preparing Work Space

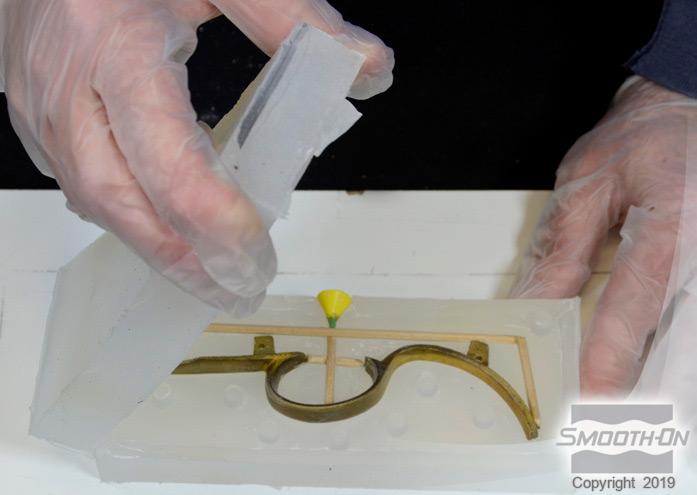

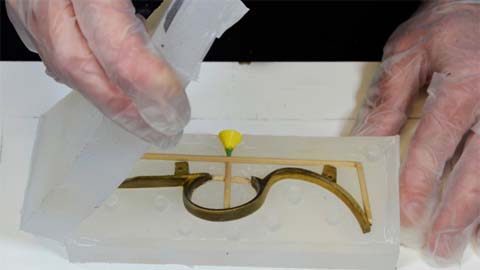

A brass trigger guard from a flintlock pistol is clayed-up half way around with a sulfur-free clay. Then thin wooden dowels are used for gating (eliminating possible air pockets). Next a sprew/pour (which fits a wax injector) is inserted.

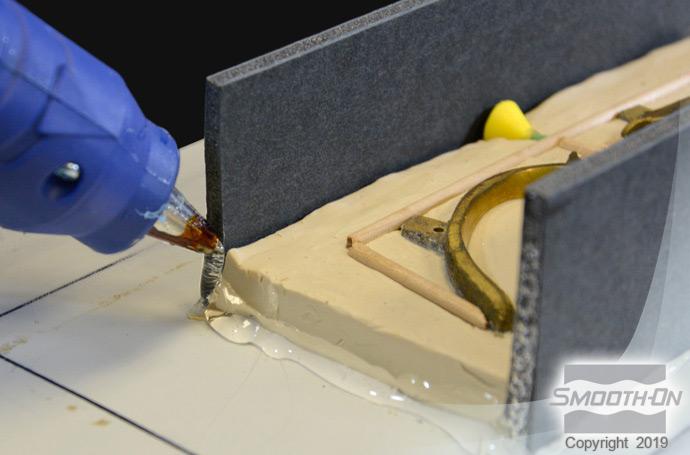

Step 2: Create A Mold Box

Foam board is glued together to create a mold box and also to seal the exterior so poured silicone is contained. Keys for registration are created with the end of an exacto knife. The mold box is now ready for the first silicone pour.

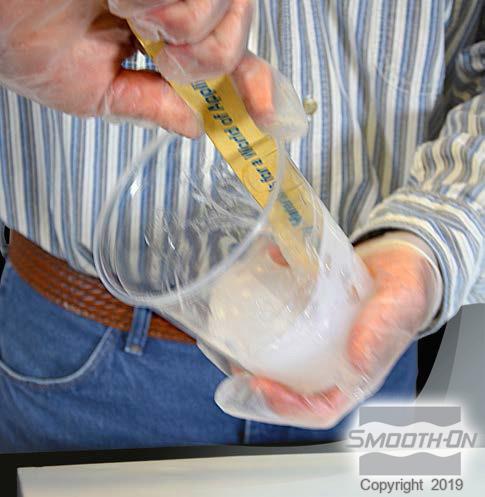

Step 3: Dispensing and Mixing of Sorta-Clear 37

SORTA-Clear® 37 Translucent Silicone Rubber is used for the application. The SORTA-Clear® 37 silicone rubber is mixed 1A to 1B by volume. The silicone is double-mixed to ensure both A and B are completely mixed for a complete cure. Make sure that you scrape the sides and bottom of your mixing container several times for a proper mix.

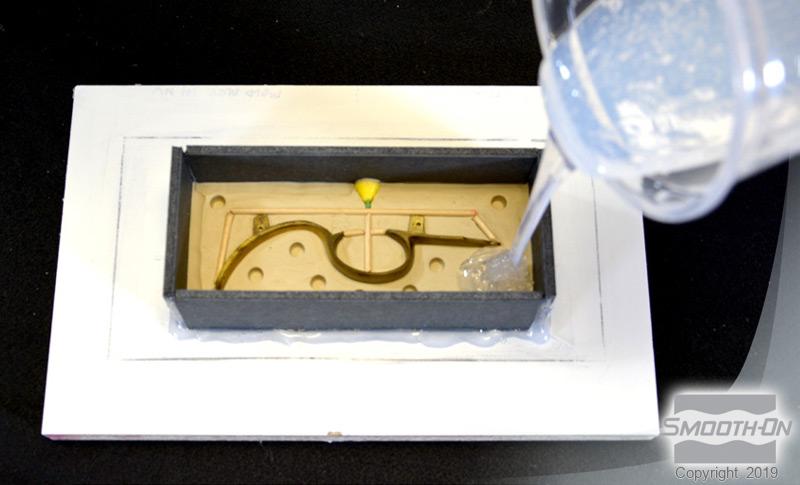

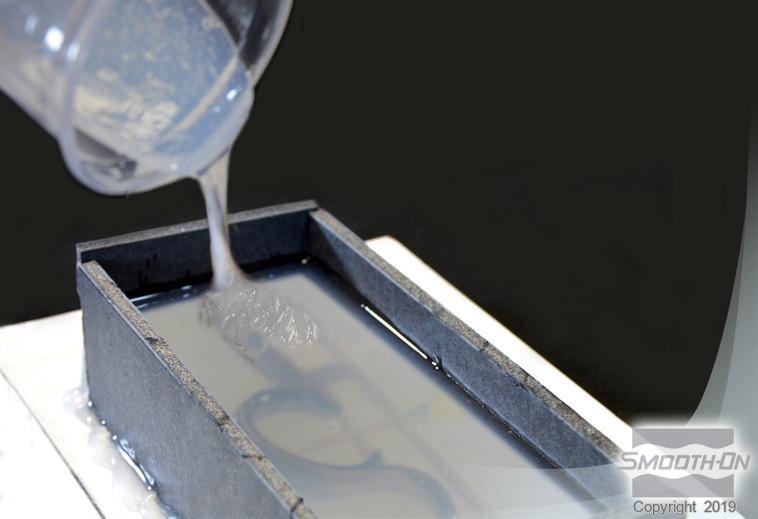

Step 4: Vacuum Degass and Pour Sorta-Clear 37

The mixed SORTA-Clear® 37 is vacuum degassed in a vacuum chamber which pulls 29 inches of mercury. The silicone is then poured into the mold box. Visibility is important in this application in order to view the hot wax when it’s injected into the mold.

Step 5: Remove Clay, Apply Ease Release 205 and Mix/Pour Sorta-Clear 37

After the clay is removed, Ease Release 205 is poured into a cup. Ease Release 205 is brushed onto the cured silicone. Let dry, and then apply another light coat of the Ease Release 205 and let dry. Mix the Sorta-Clear 37 and pour into the mold box.

Step 6: Demold Sorta-Clear 37

After the silicone cures, the mold box is removed. Then the original trigger guard and all the wooden gating dowels are removed. A perfect two-part mold is revealed which is ready to be injected with wax.

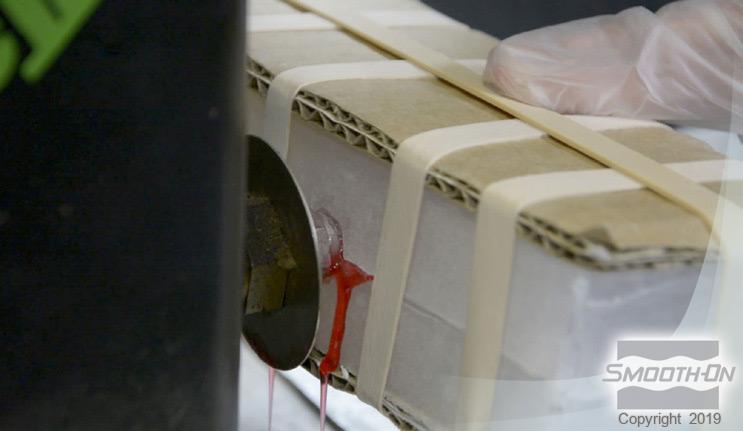

Step 7: Mold Injection and Demold Wax Casting

Thick cardboard placed on both sides of the mold and held in place with rubber bands for consistant pressure on the mold without distorting the shape. Wax is then injected into the mold and is visible through the translucent silicone. After the hot wax hardens,a perfect wax casting is revealed. Multiple wax castings are created and the flashing is then chased/removed. The wax castings are then ready for spruing as part of the remaining lost wax process. Afoundry may cast silver, gold, brass or bronze using the lost-wax casting process.