How To Make a 2 Part Trigger Guard Mold

Step 7: Mold Injection and Demold Wax Casting

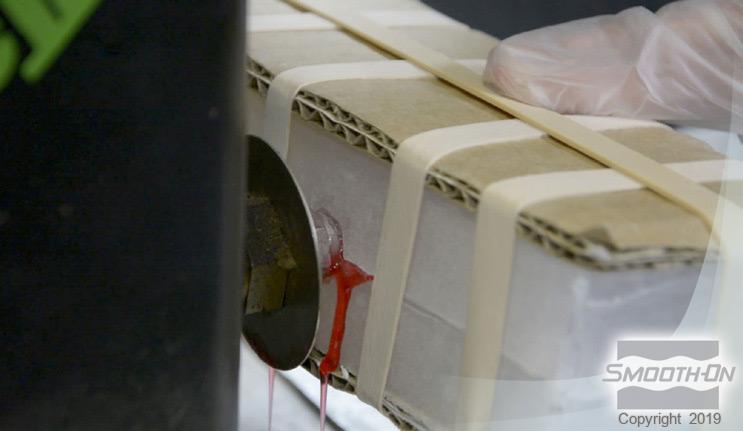

Thick cardboard placed on both sides of the mold and held in place with rubber bands for consistant pressure on the mold without distorting the shape. Wax is then injected into the mold and is visible through the translucent silicone. After the hot wax hardens,a perfect wax casting is revealed. Multiple wax castings are created and the flashing is then chased/removed. The wax castings are then ready for spruing as part of the remaining lost wax process. Afoundry may cast silver, gold, brass or bronze using the lost-wax casting process.