How To Reproduce a Sea Sponge using Liquid Plastic

Step 2: Dispensing, Mixing, and Applying Dragon Skin 10 Medium

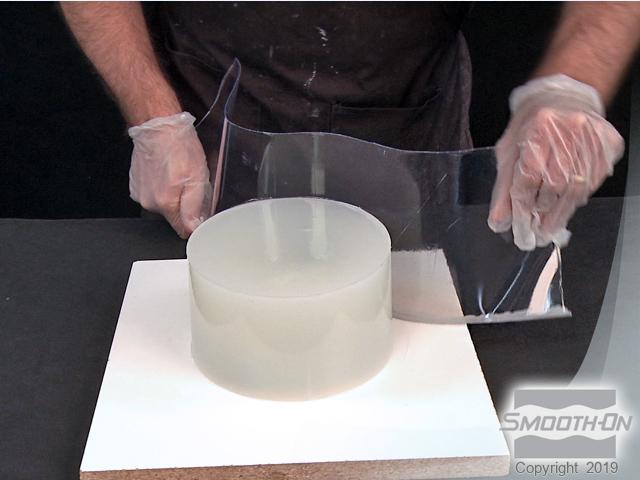

The Sea Sponge original model is highly detailed with deep undercuts. Choosing the wrong mold rubber will result in sticking or damage to the rubber mold. The best mold rubber choice for making a mold of this piece is Dragon Skin 10, which is a soft, elastic silicone rubber with very high tear strength.

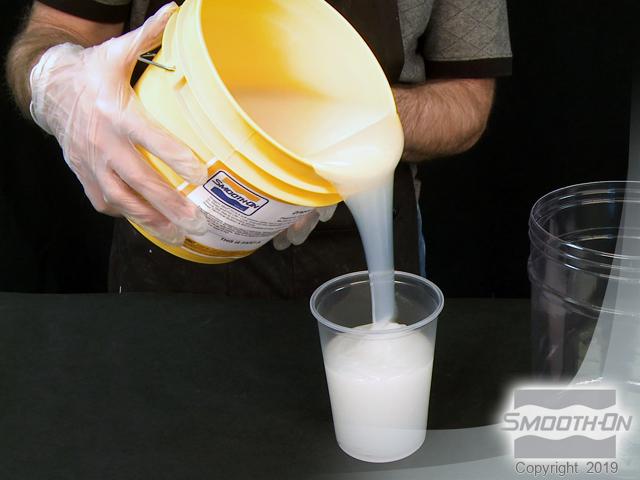

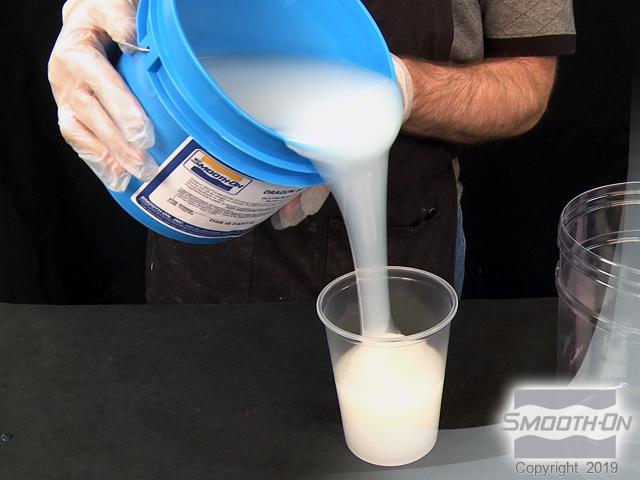

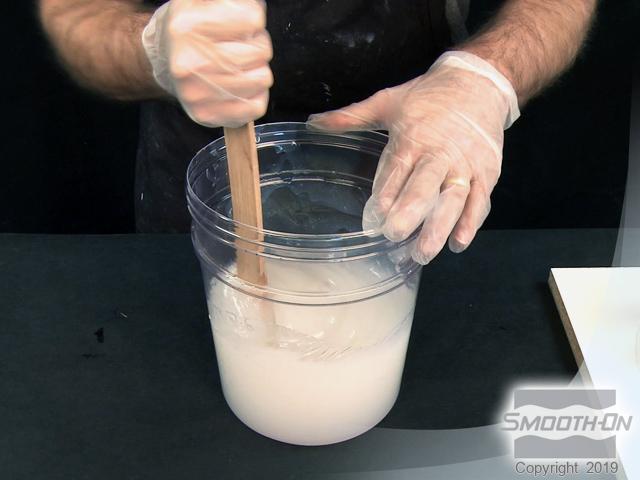

Dispense part A of Dragon Skin 10 and then seperately dispense an equal amount of part B. Mix parts A and B together thoroughly. Place your mold rubber into a vacuum chamber to remove air bubbles. Your vacuum must pull 29 inches of mercury for complete vacuum.

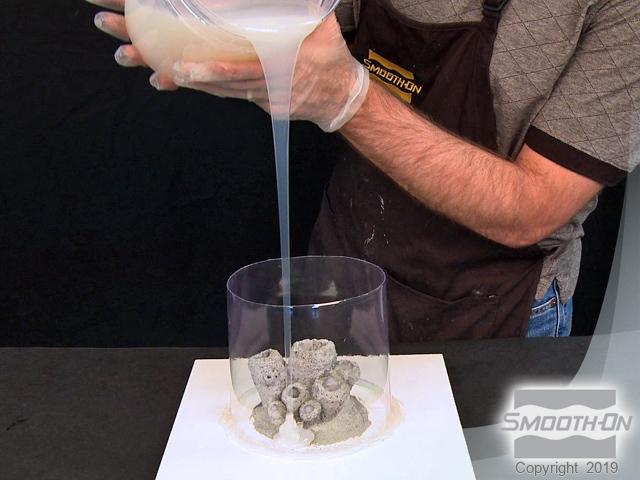

Pour the rubber into the lowest part of the containment field in a long, thin stream. Let it rise over the model and seek its own level. Let the rubber cure for at least 5 hours.