How To Rotocast Resin for Lightweight Displays

Step 2: Roto‑Casting Smooth‑Cast 65D

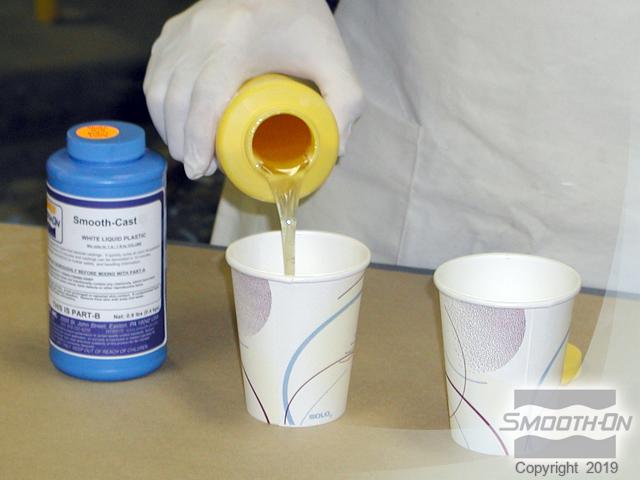

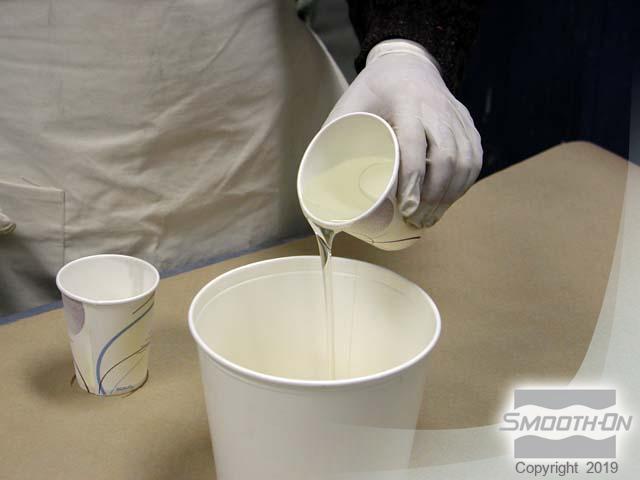

Part A and B of Smooth-Cast® 65D are dispensed and combined in a mixing container. Both parts are then thoroughly mixed for 30 seconds. The mixture is poured into the mold through the opening in the cap board. A silicone plug is used to seal the hole in the cap board.

The rotational casting machine is turned on and the large arm rotates one way, while the base rotates the other way. This 360° rotation ensures that the liquid plastic is being uniformly distributed to all parts of the mold surface. After about 10 minutes the machine is stopped and the silicone plug is removed and a punching tool is used to punch a small hole in the partially cured casting.